Microesferas de aluminossilicato (cenospheres light fraction of fly ash, bottom ash microspheres , microspheres energy ashes) are hollow beads with a size range of 20-500 microns (most often, 100 – 250 microns) and a by-product of coal burning power plants.

Compared to irregular-shaped and partially-spherical fillers, the 100% spherical shape of Ceramic Microspheres, provides improved processing and performance.Being inert it is not affected by solvents, water, acids or alkalis. They are 75% lighter than other minerals currently used as a filler or extender.

A combinação única de qualidades deste produto, como formato esférico quase ideal, baixa densidade aparente, alta resistência mecânica, estabilidade térmica e inércia química, proporcionou uma ampla gama de aplicações, conforme abaixo:

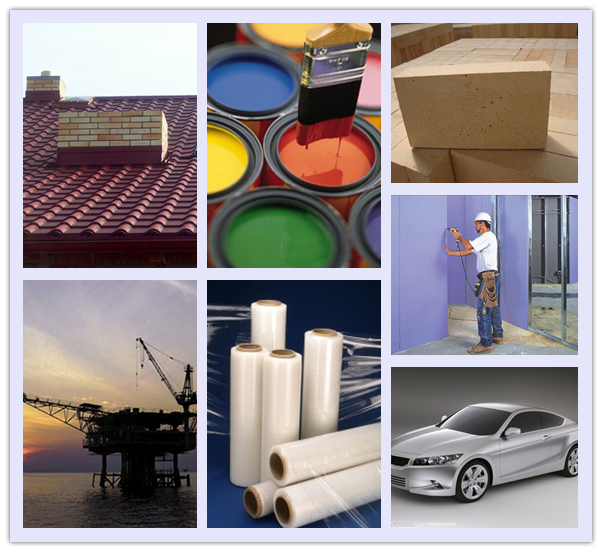

1. Construção: concreto ultraleve, gesso isolante e argamassas de alvenaria e outros tipos de misturas secas, cobertura de isolamento térmico e acústico no dispositivo de estruturas de cobertura e fachada, pisos, bem como preparação de isolamento térmico para pisos.

2.Paints Coating: Cenospheres are special additives that both chemists and formulators in the paints and coatings industry are using to enhance their products. A sphere has the lowest surface area of any shape.As a result, these hollow ceramic microspheres reduce resin demand and increase volume loading capacity.

3.Oil Field: oil well cements, drilling muds, grinding materials, explosives.

Cenosferas têm sido usadas na cimentação de campos petrolíferos há algum tempo. Durante um trabalho de cimentação, as Cenosferas agem para diminuir a densidade da pasta sem aumentar o teor de água. Isso, por sua vez, fornece melhor resistência à compressão ao cimento.

4.Ceramics: Refractories, Castables, Tile, Fire Bricks, Aluminium Cement, Insulating materials, Coatings.

5.Plastics: Cenospheres are an excellent lightweight filler for plastics and continue to grow in popularity and use. Not only do they reduce the cost of the composite but Cenospheres often impart performance improvements that might otherwise not have been achieved. It is used in all types of Moulding, Nylon, Low Density Polyethylene and Polypropylene.

6.Automotive: composites, engine parts, sound proofing materials, undercoatings.