アルミノケイ酸塩微粒子 (cenospheres light fraction of fly ash, bottom ash microspheres , microspheres energy ashes) are hollow beads with a size range of 20-500 microns (most often, 100 – 250 microns) and a by-product of coal burning power plants.

Compared to irregular-shaped and partially-spherical fillers, the 100% spherical shape of Ceramic Microspheres, provides improved processing and performance.Being inert it is not affected by solvents, water, acids or alkalis. They are 75% lighter than other minerals currently used as a filler or extender.

この製品は、ほぼ理想的な球形、低い嵩密度、高い機械的強度、熱安定性、化学的不活性といった特性を独自に組み合わせており、以下のように幅広い用途に使用されています。

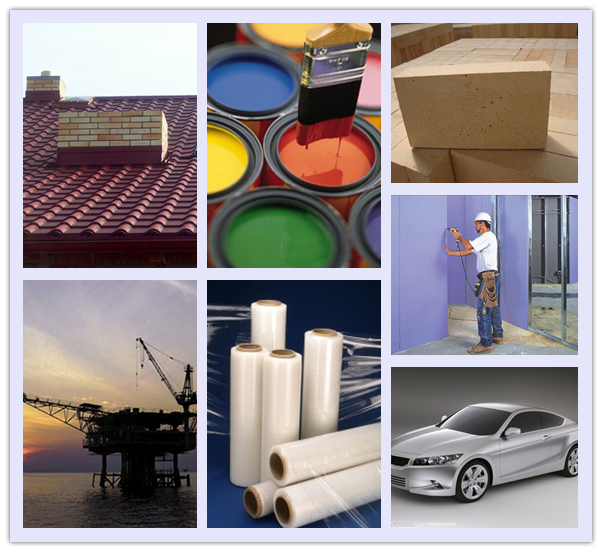

1.建設:超軽量コンクリート、断熱石膏および石工用モルタル、およびその他のタイプのドライミックス、屋根およびファサード構造、床の断熱および遮音カバー、ならびに床の断熱材の準備。

2.Paints Coating: Cenospheres are special additives that both chemists and formulators in the paints and coatings industry are using to enhance their products. A sphere has the lowest surface area of any shape.As a result, these hollow ceramic microspheres reduce resin demand and increase volume loading capacity.

3.Oil Field: oil well cements, drilling muds, grinding materials, explosives.

セノスフィアは、油田のセメント固化に長年使用されてきました。セメント固化作業中、セノスフィアは水分量を増やすことなくスラリーの密度を下げる働きをします。これにより、セメントの圧縮強度が向上します。

4.Ceramics: Refractories, Castables, Tile, Fire Bricks, Aluminium Cement, Insulating materials, Coatings.

5.Plastics: Cenospheres are an excellent lightweight filler for plastics and continue to grow in popularity and use. Not only do they reduce the cost of the composite but Cenospheres often impart performance improvements that might otherwise not have been achieved. It is used in all types of Moulding, Nylon, Low Density Polyethylene and Polypropylene.

6.Automotive: composites, engine parts, sound proofing materials, undercoatings.