Cenosphere or Hollow ceramic microspheres paint additives

Cenosphere are lightweight, inert, hollow, nonmetallic spherical materials, composed largely of silica (SiO2) and alumna (Al2O3) compositions of Cenospheres are similar with glass and ceramic.

1.Those hollow glass particles have also been called hollow ceramic spheres and micro spheres.

2.Due to their unique combination of spherical shape, high strength in compressing, good sound and thermal insulation,

Cenospheres are utilized as a high performance filler material, that can replace other mineral filler.

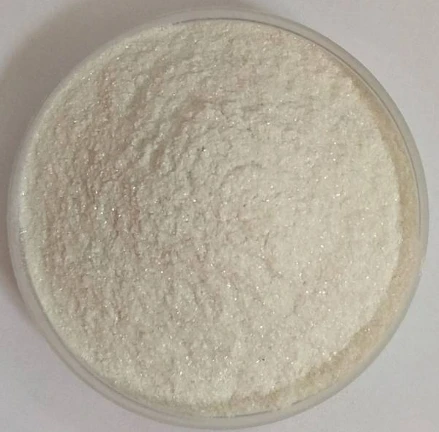

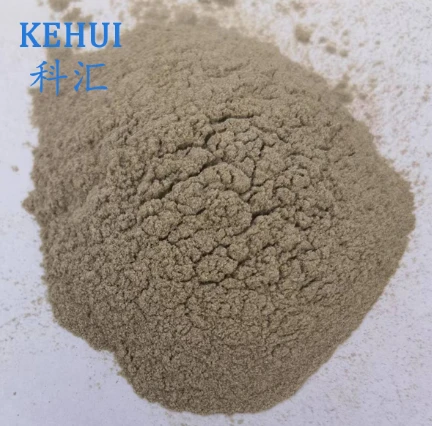

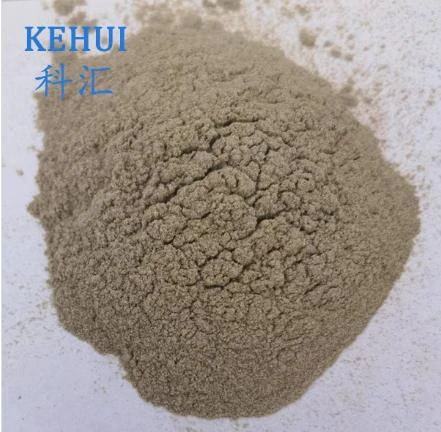

Apperance:

| Size( μm ) | 20-500 |

| Shape | Spherical |

| Color | Grey,White |

Applications:

Ceramics: Refractories, Castables, Tile, Fire Bricks, Aluminium Cement, Insulating materials, Coatings.

Plastics: BMC, SMC, Injection Molding, Moulding, Extruding, PVC Flooring, Film, Nylon, HDPE, LDPE, Polypropylene.

Construction: Speciality Cements, Mortars,Grouts,Stucco, Roofing Materials, Acoustical Panels, Coatings, Shotcrete, Gunite.

Automotive: Composites, Under coatings, Tires, Engine Parts, Brake Pads.

Energy and Technology: Oil Well Cements,Drilling Muds,Industrial Coatings,Grinding Materials,Aerospace Coating&Composites,Explosives

Paint/Coatings: Non-slip Industrial Paints Marine Non-slip Paints Tennis Court Paints

Corrosion Resistant Coatings Textured Paints Thermally Insulating Coatings Anti-condensation Coatings

Specifications of Cenosphere:

|

Grade No. |

TX |

TS |

TS-100 |

TST-100 |

|

Al2O3 |

27%min. |

25-35% |

25-35% |

25-35% |

|

SiO2 |

50-65% |

50-65% |

50-65% |

50-65% |

|

Floating Rate |

75%min. |

95%min. |

95%min. |

95%min. |

|

Size |

-500micron 95%min. |

-420micron 95%min. |

-150micron 95%min. |

-150micron 95%min. |

|

Bulk Density |

0.45-0.55g/cc |

0.35-0.45g/cc |

0.33-0.45g/cc |

0.33-0.45g/cc |

|

True Density |

- |

- |

- |

0.8-0.95g/cc |

|

Loi |

4%max |

2%max |

2%max |

2%max |

|

Moisture |

0.5%max. |

0.5%max. |

0.5%max. |

0.5%max. |

|

Color |

light grey |

light grey |

off white |

off white |

Main Advantages of Using Cenosphere:

1)Reduced Raw Materials Cost

2)Improved Flowability

3)Reduced Resin Demand

4)Improved Insulation Values

5)Reduced End Product Weight

6)Resistant to Resin Absorption