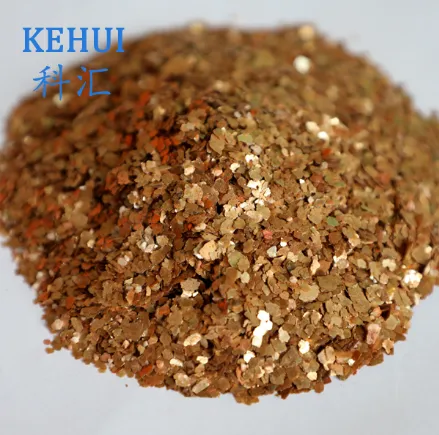

我公司生产的煅烧云母系列产品采用高温工艺制成,色泽鲜艳,品质优良,是特种焊接材料、一般建筑材料、电绝缘体的最佳选择。

In the world of industrial minerals, calcined mica has earned a respected reputation for its enhanced properties and wide range of applications. By subjecting natural mica to controlled heating processes, calcined mica undergoes physical and chemical changes that improve its thermal stability, hardness, and resistance to environmental degradation. These attributes make calcined mica a valuable material across industries such as construction, coatings, plastics, and electronics. As the demand for more durable and efficient materials continues to grow, calcined mica stands out as a refined choice for businesses seeking superior performance.

Calcined Mica Powder: Fine-Tuned for Industrial and Decorative Use

The development of calcined mica powder has opened new possibilities for industries that require fine, consistent, and highly stable fillers. Produced by grinding and processing calcined mica, this powder form retains all the beneficial properties of the original mineral while offering easier integration into various formulations. Calcined mica powder is particularly valued in applications where thermal resistance, anti-corrosion properties, and improved mechanical strength are needed, such as in paints, coatings, plastics, and rubber products.

Manufacturers choose calcined mica powder because of its ability to enhance the flexibility and strength of finished goods without compromising appearance. In the coatings industry, for instance, calcined mica powder improves the weather resistance and durability of exterior paints, ensuring longer service life and reduced maintenance costs. Its inert nature and compatibility with other compounds also make it an ideal additive in advanced composites and specialty construction materials.

Calcined Mica for Decoration: Bringing Natural Beauty to Modern Designs

Beyond industrial uses, calcined mica for decoration has gained significant popularity for its ability to bring a natural, radiant touch to architectural and design projects. The controlled calcination process enhances the sparkle and color stability of mica, making calcined mica for decoration an excellent choice for creating luxurious, textured finishes in wall panels, countertops, flooring, and artistic installations.

Designers and architects appreciate calcined mica for decoration for its unique aesthetic qualities, including its subtle luster, range of natural colors, and ability to catch and reflect light beautifully. Additionally, its excellent resistance to moisture, heat, and chemical exposure ensures that decorative surfaces maintain their visual appeal even in demanding environments. Whether incorporated into high-end residential interiors or commercial spaces aiming for a touch of natural elegance, calcined mica for decoration adds both visual interest and functional durability.

The Versatility of Calcined Mica Across Industries

The adaptability of calcined mica across multiple sectors highlights its importance as a versatile mineral resource. In the electronics industry, calcined mica serves as a high-performance insulating material capable of withstanding elevated temperatures and electrical stress. In plastics and rubber manufacturing, it reinforces products by enhancing tensile strength and dimensional stability, thereby extending product life cycles.

In construction, calcined mica is integrated into cement and concrete formulations to improve crack resistance and surface finish. Meanwhile, in the coatings industry, its presence boosts corrosion resistance and offers a visually appealing shimmer that enhances surface textures. Furthermore, with its increasing role in decorative applications, calcined mica for decoration continues to demonstrate that it is as aesthetically impressive as it is functionally essential.

煅烧云母 FAQs

What makes calcined mica different from natural mica?

Calcined mica undergoes a thermal treatment process that transforms its physical structure and enhances its properties. Compared to natural mica, calcined mica has improved thermal stability, increased hardness, and better chemical resistance. These enhancements make it more suitable for high-performance industrial applications as well as premium decorative uses.

What are the common industrial applications of calcined mica powder?

Calcined mica powder is widely used in industries such as paints, plastics, rubber, and construction. It acts as a reinforcing filler that improves thermal resistance, mechanical strength, and weather durability. In coatings, calcined mica powder enhances anti-corrosion properties, while in plastics, it contributes to better heat distortion resistance and dimensional stability.

How is calcined mica for decoration applied in interior design projects?

Calcined mica for decoration can be incorporated into wall finishes, flooring systems, countertops, and artistic panels to add a luxurious, natural shimmer. It is often embedded into plaster, resin, or surface coatings, providing a reflective and textured finish. Because of its enhanced durability and resistance to environmental factors, calcined mica for decoration maintains its aesthetic quality over time.

Is calcined mica safe for use in consumer products?

Yes, calcined mica is considered safe for use in a wide range of consumer products. It is chemically inert, non-toxic, and stable under normal usage conditions. When processed and handled properly, calcined mica poses minimal health or environmental risks, making it a trusted material in everything from industrial coatings to decorative surfaces.

How do I choose the right supplier for calcined mica?

Selecting a reliable supplier for calcined mica involves considering factors such as product consistency, purity levels, technical support, and adherence to industry standards. Reputable suppliers provide detailed specifications and can offer tailored solutions based on specific industrial or decorative requirements. Ensuring that the supplier can deliver consistent quality across batches is crucial for achieving the best results with calcined mica.

-

The Versatile World of Phlogopite Mica: Properties, Forms, and Applications消息Jul.14,2025

-

The Versatile Applications of Calcined Mica: From Decoration to Industrial Use消息Jul.14,2025

-

The Role of Muscovite Mica in Industrial Insulation Materials消息Jul.14,2025

-

The Benefits of Using Expanded Clay Pebbles in Hydroponics and Soil Gardening消息Jul.14,2025

-

Innovative Applications of Mica Flake in Paints and Coatings消息Jul.14,2025

-

Gardening Expanded Clay Usage: A Complete Guide消息Jul.14,2025

-

The Use of Natural Mica Powder in Skincare Products消息Jun.11,2025

-

The Versatile World of Phlogopite Mica: Properties, Forms, and Applications消息Jul.14,2025

-

The Versatile Applications of Calcined Mica: From Decoration to Industrial Use消息Jul.14,2025

-

The Role of Muscovite Mica in Industrial Insulation Materials消息Jul.14,2025

-

The Benefits of Using Expanded Clay Pebbles in Hydroponics and Soil Gardening消息Jul.14,2025

-

Innovative Applications of Mica Flake in Paints and Coatings消息Jul.14,2025

-

Gardening Expanded Clay Usage: A Complete Guide消息Jul.14,2025

-

The Use of Natural Mica Powder in Skincare Products消息Jun.11,2025