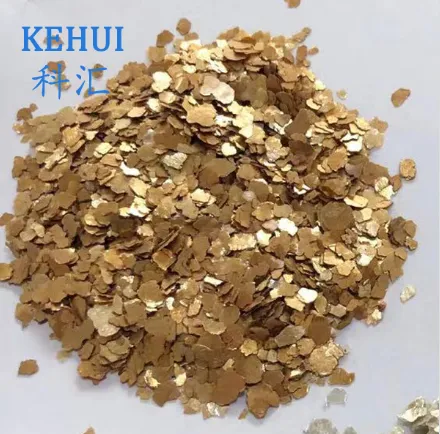

In the vast landscape of industrial materials, phlogopite mica stands out as a versatile and valuable mineral. With its distinct phlogopite mica properties and the unique characteristics of phlogopite mica flakes, it has found its way into numerous industrial sectors.

Understanding Phlogopite Mica Properties

Phlogopite mica possesses a set of properties that make it highly desirable in various industries. Chemically, it is a potassium magnesium aluminum silicate hydroxide. One of the most notable phlogopite mica properties is its excellent heat resistance. It can withstand high temperatures without degrading, making it suitable for applications where thermal stability is crucial. Additionally, phlogopite mica has good electrical insulation properties, low thermal conductivity, and is resistant to chemicals and moisture. Its ability to be easily split into thin phlogopite mica flakes further enhances its usability in different industrial processes.

Electrical and Electronics Industry with Phlogopite Mica

In the electrical and electronics industry, phlogopite mica plays a vital role. Thanks to its outstanding electrical insulation phlogopite mica properties, it is used to manufacture insulators, capacitors, and electrical connectors. Phlogopite mica flakes can be used to create insulating layers in electrical devices, protecting sensitive components from electrical short - circuits and ensuring the safe and efficient operation of equipment. The high heat resistance of phlogopite mica also makes it suitable for use in high - temperature electrical applications, such as in motors and generators, where it can prevent overheating and extend the lifespan of the devices.

Construction and Building Materials with Phlogopite Mica Flakes

Phlogopite mica flakes are widely used in the construction and building materials industry. When added to paints, plastics, and rubber, they enhance the mechanical strength, durability, and weather resistance of these materials. The phlogopite mica properties of chemical resistance and moisture resistance help protect the building materials from environmental damage, ensuring a longer service life. In fire - resistant materials, phlogopite mica is a key ingredient due to its high melting point and heat - resistant nature. It can prevent the spread of fire and provide additional time for evacuation in case of a fire emergency, making buildings safer.

Automotive and Aerospace Industries Utilizing Phlogopite Mica

Both the automotive and aerospace industries benefit from the unique phlogopite mica properties. In automotive manufacturing, phlogopite mica is used in engine components to withstand high temperatures and reduce friction. Its electrical insulation properties are also utilized in the electrical systems of vehicles. In the aerospace sector, where lightweight and high - performance materials are essential, phlogopite mica - based composites are used in aircraft parts. The heat resistance and strength of phlogopite mica make it suitable for components exposed to extreme conditions during flight, such as engine parts and thermal protection systems.

Other Industrial Applications of Phlogopite Mica

Beyond the major industries mentioned above, phlogopite mica has applications in many other sectors. In the cosmetics industry, phlogopite mica flakes are used to add a shimmering effect to makeup products. In the paper industry, it is added to improve the strength and printability of paper. In the foundry industry, phlogopite mica is used as a refractory material to line furnaces and crucibles, thanks to its high heat resistance and chemical stability. These diverse applications highlight the versatility of phlogopite mica across different industrial fields.

Industrial Applications of Phlogopite Mica FAQS

What makes phlogopite mica properties different from other types of mica?

Phlogopite mica properties distinguish it from other micas mainly due to its chemical composition. It contains a relatively high amount of magnesium, which contributes to its excellent heat resistance and chemical stability. Compared to some other micas, phlogopite mica can better withstand high temperatures and harsh chemical environments, making it more suitable for industrial applications that require extreme conditions tolerance.

How are phlogopite mica flakes processed for industrial use?

Phlogopite mica flakes are processed through a series of steps. First, the raw phlogopite mica ore is mined. Then, it is crushed and ground to break it into smaller pieces. After that, through processes like sieving and classification, the mica is separated into different sizes of phlogopite mica flakes according to industrial requirements. Sometimes, surface treatment may also be applied to improve the compatibility of the flakes with other materials in specific applications.

Can phlogopite mica be used in high - voltage electrical applications?

Yes, phlogopite mica is well - suited for high - voltage electrical applications. Its superior electrical insulation phlogopite mica properties enable it to prevent electrical leakage and breakdown even under high - voltage conditions. It can effectively insulate electrical components, ensuring the safe and reliable operation of high - voltage electrical systems, such as in power transmission and distribution equipment.

What role does phlogopite mica play in improving the durability of building materials?

Phlogopite mica improves the durability of building materials in several ways. Its chemical resistance protects materials from degradation caused by exposure to acids, alkalis, and other chemicals in the environment. The phlogopite mica properties of high strength and hardness enhance the mechanical properties of materials, making them more resistant to wear and tear. Additionally, its moisture resistance prevents water - related damage, such as mold growth and material swelling, thus extending the lifespan of building materials.

Are there any environmental concerns associated with the use of phlogopite mica?

When sourced and used responsibly, phlogopite mica has relatively low environmental impact. However, like any mining activity, improper extraction of phlogopite mica ore can lead to habitat destruction and soil erosion. Also, if waste generated during the processing of phlogopite mica and phlogopite mica flakes is not managed properly, it may cause pollution. To mitigate these concerns, sustainable mining practices and proper waste management are crucial in the phlogopite mica industry.

Are you in need of high - quality phlogopite mica or phlogopite mica flakes for your industrial applications? Our company is a leading provider of premium phlogopite mica products. With a deep understanding of phlogopite mica properties and strict quality control measures, we ensure that our products meet the highest industry standards. Whether you are in the electrical, construction, automotive, or any other industry, our phlogopite mica offerings can enhance the performance of your products. Contact us today to explore our product range and place your order!

-

The Versatile World of Phlogopite Mica: Properties, Forms, and Applicationsవార్తలుJul.14,2025

-

The Versatile Applications of Calcined Mica: From Decoration to Industrial Useవార్తలుJul.14,2025

-

The Role of Muscovite Mica in Industrial Insulation Materialsవార్తలుJul.14,2025

-

The Benefits of Using Expanded Clay Pebbles in Hydroponics and Soil Gardeningవార్తలుJul.14,2025

-

Innovative Applications of Mica Flake in Paints and Coatingsవార్తలుJul.14,2025

-

Gardening Expanded Clay Usage: A Complete Guideవార్తలుJul.14,2025

-

The Use of Natural Mica Powder in Skincare Productsవార్తలుJun.11,2025