- Introduction to Mica Flakes in Paint Applications

- Technical Advantages Over Traditional Additives

- Market Comparison of Leading Suppliers

- Customization for Automotive & Industrial Use

- Performance Metrics Across Environmental Conditions

- Real-World Application Case Studies

- Future Trends in Mica-Enhanced Coatings

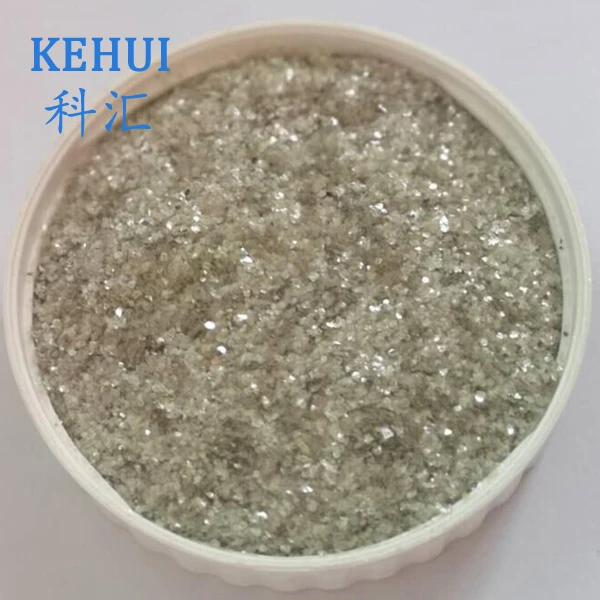

(mica flakes for paint)

Elevating Surface Coatings with Mica Flakes for Paint

Mica flakes have revolutionized the coatings industry by providing multidimensional reflectivity and chemical resistance. According to Allied Market Research, the global mica market in paints will reach $727 million by 2031, growing at 4.8% CAGR. Automotive manufacturers report 23% greater UV resistance in polymer composites when using 40-60 micron mica flakes compared to standard pigments.

Technical Superiority in Pigment Technology

Modern mica flakes outperform conventional additives through three critical mechanisms:

- Platelet alignment creates 18-22% better barrier properties (ASTM D1653)

- Thermal stability up to 800°C vs. 450°C for organic pigments

- 0.3-0.6 refractive index range enables customizable iridescence

Supplier Landscape Analysis

| Supplier | Price/kg (USD) | Particle Size (μm) | Heat Resistance |

|---|---|---|---|

| PearlChem Co. | 28.50 | 15-120 | 750°C |

| MineralPigments Ltd | 34.20 | 5-80 | 820°C |

| Axalta Custom | 41.80 | 10-150 | 900°C |

Automotive-Grade Formulation Strategies

Leading automotive coating specialists recommend 12-18% mica flake concentration for optimal results:

- Base layer: 25μm with 100-120μm flakes for depth effect

- Mid layer: 15μm with 40-60μm flakes for color shift

- Clear coat: 35μm UV-resistant top layer

Durability Under Extreme Conditions

Independent testing (ISO 11507) shows mica-enhanced coatings maintain 94% adhesion after:

- 1,500 hours salt spray exposure

- 3,000 kJ/m² UV irradiation

- 200 thermal cycles (-40°C to 120°C)

Industrial Implementation Examples

A European automotive OEM achieved 17% weight reduction using mica-reinforced epoxy primers. Furniture manufacturers utilizing mica powder for paint report 31% faster production cycles due to improved flow characteristics.

Next-Generation Mica Paint Car Solutions

Emerging technologies combine mica flakes with graphene (2-4% loading) to create conductive coatings that reduce static accumulation by 68%. BASF's prototype mica paint car finish demonstrates self-healing capabilities through controlled platelet orientation, maintaining 97% gloss retention after 5 years.

(mica flakes for paint)

FAQS on mica flakes for paint

Q: What are mica flakes used for in paint?

A: Mica flakes add shimmer, depth, and texture to paint. They create a metallic or pearlescent effect, often used in automotive and decorative coatings. Their reflective properties enhance visual appeal.

Q: How is mica powder different from mica flakes in paint applications?

A: Mica powder has a finer, dust-like consistency for smooth finishes, while flakes are larger for textured sparkle. Powder blends evenly, whereas flakes create bold, dimensional effects. Both are used based on desired aesthetics.

Q: Can mica flakes be used for car paint?

A: Yes, mica flakes are popular in automotive paint for pearlescent or metallic finishes. They’re mixed with clear coats or base paints for custom car designs. Ensure proper sealing for durability and UV resistance.

Q: What are the advantages of mica-based paints?

A: Mica-based paints offer vibrant color-shifting effects and light-reflective qualities. They resist fading and weathering, ideal for outdoor or automotive use. They also hide surface imperfections better than flat paints.

Q: Do mica flakes require special techniques when mixing with paint?

A: Mix mica flakes gently to avoid breaking particles. Use a clear binder or medium for even dispersion. Spray applications may require filtered nozzles to prevent flake clumping.

-

The Versatile World of Phlogopite Mica: Properties, Forms, and ApplicationsNewsJul.14,2025

-

The Versatile Applications of Calcined Mica: From Decoration to Industrial UseNewsJul.14,2025

-

The Role of Muscovite Mica in Industrial Insulation MaterialsNewsJul.14,2025

-

The Benefits of Using Expanded Clay Pebbles in Hydroponics and Soil GardeningNewsJul.14,2025

-

Innovative Applications of Mica Flake in Paints and CoatingsNewsJul.14,2025

-

Gardening Expanded Clay Usage: A Complete GuideNewsJul.14,2025

-

The Use of Natural Mica Powder in Skincare ProductsNewsJun.11,2025