High-Quality Perlite Is Ideal for Insulation & Lightweight Concrete Pure & Raw Perlite Supplier

Perlite Is the Modern Advantage: Unlock the Potential of Pure and Raw Perlite Today

Imagine tackling an industrial project, only to discover that traditional insulation is heavy, underperforms, and drives up your costs. Did you know that, according to Statista, the global need for advanced insulation materials is growing at over 6% annually? In the construction, horticulture, and foundry fields, outdated solutions can cause up to 25% more energy loss—eating into profits and contaminating your brand’s reputation for sustainability. Enter a game-changer: Perlite. In this post, you’ll discover how pure perlite and raw perlite are redefining industry standards, elevating product performance, and maximizing your returns. You’ll see why industries are rapidly shifting to perlite-based options—and how your business can get ahead.

(perlite is)

Perlite Is Smart: Technical Advantages That Outperform the Rest

Why choose perlite? You want a material that’s ultra-lightweight, stable, and non-combustible, right? Perlite is exactly that. It’s a volcanic glass with a unique ability: when heated, it expands up to 20 times its original size, trapping millions of tiny air pockets. These pockets make pure perlite an outstanding insulator—delivering up to 80% higher thermal resistance than traditional mineral wool.

Let’s talk specs. Here’s why perlite wins:

| Property | Pure Perlite | Raw Perlite | Mineral Wool |

|---|---|---|---|

| Thermal Conductivity (W/mK) | 0.033–0.058 | 0.04–0.06 | 0.035–0.045 |

| Bulk Density (kg/m³) | 32–40 | 900–1100 | 60–120 |

| Fire Resistance | Non-combustible, A1 | Non-combustible | A1, melts at high temps |

| Moisture Retention | Excellent | Low–Med | Limited |

What does this mean for you? Perlite-based products mean fewer losses from heat transfer, a lighter load for shipping, and trouble-free installation. It excels in refractory cement and perlite mixes, boosting longevity and providing industry-leading fire protection. You get reliable, proven performance—every single time.

Manufacturer Matters: Why Source the Best Pure and Raw Perlite?

The global perlite market is projected to exceed $1.5 billion by 2027. But where you buy matters even more. Not all perlite is

equal. Why settle for a supplier who cuts corners, when your results depend on purity and grade?

Consider this:

- Premium pure perlite is processed for maximum yield and uniform particle size.

- Raw perlite direct from the mine may vary in quality—affecting your end product consistency.

- Trusted manufacturers offer batch certifications and custom screening—giving you peace of mind for every purchase.

- Global distributors (like Perlite Innovators Inc.) guarantee prompt delivery and 24/7 support.

Choose the wrong supplier, and you risk product recalls, downtime, or failing fire safety tests. Partner with industry leaders, and you’re guaranteed performance—plus the expert advice you deserve.

Custom Solutions: Perlite Is Versatile for Every Need

No two businesses are the same. That’s why a one-size-fits-all approach leaves money on the table. Perlite is uniquely versatile—it molds to your specific project needs. Want to know how?

- Custom particle size blends for hydroponics, soil amendments, and concrete—improving water retention and drainage by up to 35%.

- Engineered raw perlite for high-performance refractory cement and perlite mixes, tolerating temperatures above 1000°C.

- Coating or impregnation options—perfect for odor absorption or specialty filtration systems in pharmaceutical and brewing plants.

- Lightweight aggregate grades for load-bearing panels, cutting construction weight by up to 50% vs. traditional additives.

Ask about a custom blend. You’ll be amazed how much efficiency you can unlock. And if you don’t know where to start, just ask—you’ll get a no-cost sample to test the advantages for yourself.

Proven Application Cases: Perlite Is the Reliable Choice

Let’s see how perlite performs in the real world. Here are a few eye-opening cases—maybe you’ll spot your next project among them.

- Greenhouse Growers: One Florida grower switched to pure perlite for propagation trays, seeing 22% faster root establishment and slashing water waste by one-third.

- Industrial Kilns: A steel manufacturer replaced traditional insulation with a refractory cement and perlite system. Energy bills dropped by $11,000 USD per quarter—plus, downtime shrank by 40% during maintenance.

- Building Contractors: In seismic regions, lightweight raw perlite concrete fills are now standard. Contractors reduce structural load and meet safety regs with ease.

- Water Filtration Plants: Custom perlite filtration cakes outperform diatomaceous earth—capturing finer particles and enabling faster cleaning cycles.

Big or small, these results prove one thing: Perlite is the solution you can count on, no matter your challenge.

Conclusion: Choose Advanced Perlite, Stay Ahead

Why risk your project—and your reputation—with second-rate materials? Pure perlite and raw perlite unlock lighter, stronger, greener solutions. From refractory cement and perlite blends to top-tier filtration, perlite’s technical, economic, and sustainability advantages are proven by real data—and real clients just like you.

Ready to upgrade? Perlite Innovators Inc. is America’s certified source of industrial-grade perlite, tailored to your exact need. With premium quality, on-time delivery, and expert support, we take your project from “what if” to “what’s next.”

Contact our expert team today for a free consultation and quote. Don’t let your competition get ahead—discover how perlite is the key to your future success.

Professional FAQs About Perlite Products

Q1: What is perlite and how is it made?

Perlite is a natural volcanic glass. It’s mined and then rapidly heated to about 1600°F. This sudden expansion “pops” the rock, creating tiny air pockets—making perlite super lightweight and absorbent. Pure perlite comes from further refining and screening for higher performance.

Q2: How is pure perlite different from raw perlite?

Raw perlite is the unprocessed ore straight from the mine. Pure perlite undergoes further processing, achieving consistent particle size, enhanced cleanliness, and optimized insulating properties. It’s the top choice for sensitive industrial and horticultural applications.

Q3: Why combine refractory cement and perlite?

Combining refractory cement and perlite creates a lightweight, heat-resistant, and fireproof layer—perfect for kilns, furnaces, and fireplaces. Perlite enhances insulation, extends product life, and cuts energy costs by up to 25%.

Q4: What technical parameters should I check before buying perlite?

Look for bulk density (typically 32–120 kg/m³), particle size distribution, thermal conductivity, and certified non-combustibility. Trusted vendors provide lab reports with each batch. Always demand quality assurance!

Q5: Which industries use perlite the most?

Construction, horticulture, metallurgy, filtration, and pharmaceuticals. Builders love perlite for insulation and lightweight concrete. Growers rely on pure perlite for root health. Perlite’s versatility is unmatched.

Q6: How does perlite benefit sustainable construction?

Perlite is non-toxic, reusable, and aids in energy-saving designs. It reduces building weight and carbon footprint. Many LEED-certified projects now require perlite-based materials for green points.

Q7: Can I order custom perlite solutions for my project?

Absolutely! Top manufacturers, like Perlite Innovators Inc., offer custom blends and grades—from extra-fine to coarse sizing. You’ll get samples, expert advice, and reliable US-wide delivery. Just ask.

(perlite is)

FAQS on perlite is

Q: What is perlite used for?

A: Perlite is a lightweight, volcanic rock used in construction, horticulture, and insulation. It improves soil aeration and moisture retention. In construction, it provides insulation and fire resistance.Q: Is pure perlite safe for gardening?

A: Yes, pure perlite is safe and widely used to improve soil drainage and aeration. It is non-toxic and sterile. Gardeners use it to support healthy plant roots.Q: What is raw perlite?

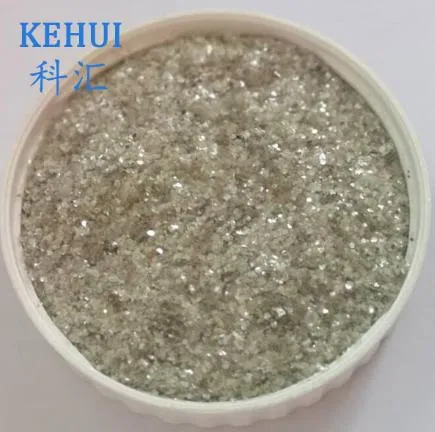

A: Raw perlite is the natural, unprocessed volcanic glass before expansion. It requires heating to pop and expand for industrial uses. Unprocessed, it appears dense and glassy.Q: How is refractory cement and perlite used together?

A: Perlite is mixed with refractory cement to create lightweight, insulating, and fire-resistant material. This combination is ideal for building pizza ovens and fireplaces. The perlite reduces weight while maintaining high heat resistance.Q: Why is perlite considered a good insulator?

A: Perlite’s expanded structure traps air, providing excellent insulation. It resists heat transfer and withstands high temperatures. This makes perlite valuable in both industrial and construction applications.-

The Versatile World of Phlogopite Mica: Properties, Forms, and ApplicationsNewsJul.14,2025

-

The Versatile Applications of Calcined Mica: From Decoration to Industrial UseNewsJul.14,2025

-

The Role of Muscovite Mica in Industrial Insulation MaterialsNewsJul.14,2025

-

The Benefits of Using Expanded Clay Pebbles in Hydroponics and Soil GardeningNewsJul.14,2025

-

Innovative Applications of Mica Flake in Paints and CoatingsNewsJul.14,2025

-

Gardening Expanded Clay Usage: A Complete GuideNewsJul.14,2025

-

The Use of Natural Mica Powder in Skincare ProductsNewsJun.11,2025