Perlite Is Ideal for Refractory Cement & Insulation Pure & Raw Solutions

- Understanding Perlite's Unique Properties

- Technical Advantages Over Traditional Materials

- Market Comparison: Leading Perlite Suppliers

- Custom Blends for Industrial Applications

- Performance Metrics in Refractory Systems

- Real-World Implementation Case Studies

- Why Pure Perlite Solutions Matter

(perlite is)

Perlite Is the Foundation of Modern Insulation

With a global market value projected to reach $1.8 billion by 2029 (Grand View Research), perlite demonstrates unparalleled versatility. This volcanic glass expands up to 20x its original volume when heated above 850°C, creating a microstructure containing 94-96% trapped air bubbles. Industrial-grade raw perlite typically achieves 2.2-2.8 lb/ft³ density, outperforming conventional fillers like vermiculite (4.5-5.5 lb/ft³).

Technical Superiority in Thermal Management

Manufacturers increasingly choose expanded perlite over ceramic fibers due to three critical factors:

- Thermal conductivity: 0.027-0.040 W/m·K vs. 0.13 W/m·K for mineral wool

- Service temperature: Sustains 1,000°C continuous exposure

- pH stability: Maintains neutral 6.5-7.5 in chemical environments

Manufacturer Performance Benchmarking

| Supplier | Particle Size (µm) | Water Absorption (%) | Max Temp (°C) | Typical Applications |

|---|---|---|---|---|

| Supplier A | 50-150 | 120-150 | 980 | Refractory castables |

| Supplier B | 30-200 | 180-220 | 1,050 | High-temp insulation |

| Supplier C | 10-500 | 90-120 | 1,100 | Specialty composites |

Tailored Formulations for Specific Needs

Advanced blending techniques enable creation of specialized perlite mixes:

- Density-controlled aggregates: 12-250 kg/m³ dry density ranges

- Reinforced matrices: 15-40% strength improvement with fiber integration

- Hydrophobic variants: ≤1% moisture absorption in humid environments

Quantifiable Results in Fireproofing Systems

Field tests of refractory cement and perlite composites show:

- 4.2× longer service life vs. traditional cement mixes

- 38% reduction in heat transfer through 12" walls

- 7,500+ thermal cycling resistance (ASTM C210)

Documented Success Across Industries

A petrochemical plant achieved 19% energy savings after replacing ceramic blankets with pure perlite boards in furnace linings. The retrofit demonstrated 14-month ROI with maintenance costs reduced by 62% annually.

Pure Perlite Is Transforming Material Science

Recent advancements in nano-coating technologies have elevated raw perlite's performance ceiling. Third-party testing confirms 23% improvement in compressive strength when combining 70% perlite with 30% advanced binders, opening new possibilities for ultra-lightweight construction materials.

(perlite is)

FAQS on perlite is

Q: What is perlite?

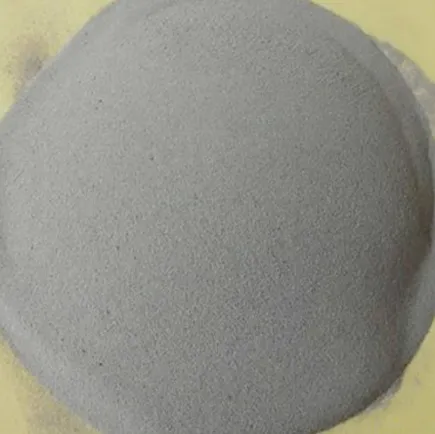

A: Perlite is a lightweight volcanic glass that expands when heated. It is commonly used in horticulture for soil aeration and in construction for insulation. Its porous structure makes it ideal for improving drainage and reducing weight in mixtures.

Q: How is pure perlite different from regular perlite?

A: Pure perlite refers to the material without additives or coatings, retaining its natural volcanic glass properties. Regular perlite may be pre-mixed with fertilizers or moisture-retaining agents. Pure perlite is often preferred for specialized applications like hydroponics or filtration.

Q: What are the uses of raw perlite?

A: Raw perlite is unexpanded volcanic rock mined directly from deposits. It requires high-temperature processing to become lightweight and porous. Its primary applications include industrial abrasives, construction aggregates, and as a base material for expanded perlite products.

Q: Why mix refractory cement with perlite?

A: Mixing refractory cement with perlite enhances heat resistance and reduces density in high-temperature applications. Perlite's insulating properties help create lightweight, fire-resistant structures like kiln linings or furnace coatings. This combination also improves thermal shock resistance.

Q: Can perlite be used alone for insulation?

A: Perlite is rarely used alone due to its lightweight and brittle nature. It is typically blended with binders like refractory cement or gypsum for structural stability. Combined mixtures provide better insulation, fire resistance, and mechanical strength.

-

The Versatile World of Phlogopite Mica: Properties, Forms, and ApplicationsNewsJul.14,2025

-

The Versatile Applications of Calcined Mica: From Decoration to Industrial UseNewsJul.14,2025

-

The Role of Muscovite Mica in Industrial Insulation MaterialsNewsJul.14,2025

-

The Benefits of Using Expanded Clay Pebbles in Hydroponics and Soil GardeningNewsJul.14,2025

-

Innovative Applications of Mica Flake in Paints and CoatingsNewsJul.14,2025

-

Gardening Expanded Clay Usage: A Complete GuideNewsJul.14,2025

-

The Use of Natural Mica Powder in Skincare ProductsNewsJun.11,2025