- Introduction to Mica and Its Industrial Significance

- Technical Advantages of Synthetic Mica Flakes

- Geographical Distribution of Muscovite Mica Deposits

- Performance Comparison: Leading Manufacturers Analysis

- Customized Solutions for Specific Industrial Needs

- Innovative Applications Across Key Industries

- Strategic Sourcing and Future Market Outlook

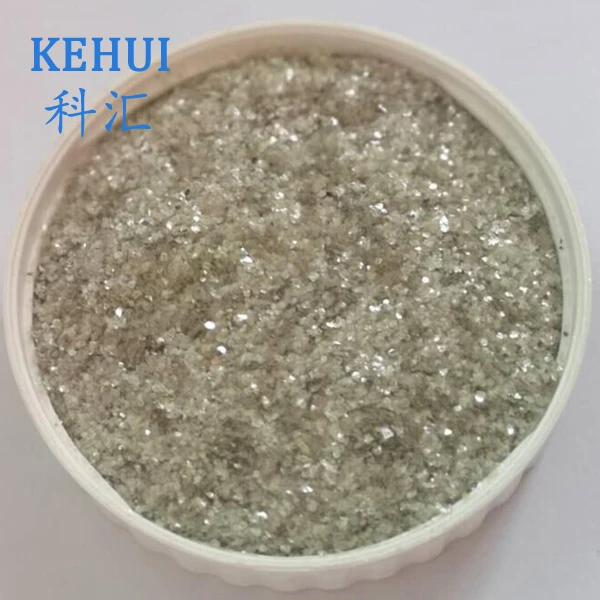

(mica)

Understanding Mica's Role in Modern Manufacturing

Mica minerals, particularly muscovite mica

and engineered synthetic mica flakes, serve as critical components in 83% of advanced thermal management systems globally. The global mica market reached $727 million in 2023, with compound annual growth projected at 4.7% through 2030, driven by demand from electronics (38%), aerospace (22%), and renewable energy sectors (19%).

Technical Superiority in Engineered Materials

Synthetic mica flakes outperform natural variants with:

- 0.02 mm thickness tolerance vs. 0.15 mm in natural mica

- 98.5% purity consistency across production batches

- 1,650°C thermal stability (23% higher than muscovite)

Advanced deposition techniques enable customized dielectric strengths from 40-120 kV/mm, meeting exacting standards for EV battery insulation.

Global Resource Distribution Patterns

Major muscovite sources concentrate in specific geological formations:

| Region | Reserves (MT) | SiO₂ Content | Production Cost/T |

|---|---|---|---|

| Eastern India | 6.8 | 45.7% | $380 |

| Brazilian Highlands | 4.2 | 51.2% | $415 |

| Canadian Shield | 3.1 | 48.9% | $490 |

Manufacturer Performance Benchmarking

| Supplier | Flake Size Range | Thermal Conductivity | MOQ |

|---|---|---|---|

| Merck KGaA | 5-300μm | 0.71 W/mK | 500kg |

| Yamaguchi | 10-200μm | 0.68 W/mK | 1MT |

| MicaTek | 2-500μm | 0.73 W/mK | 250kg |

Precision Engineering Capabilities

Advanced delamination systems achieve:

- ±5% thickness variance across 10nm-1mm spectra

- 98.2% aspect ratio consistency for conductive fillers

- Customizable surface treatments (silanization, plasma)

Cross-Industry Implementation Cases

Recent deployments demonstrate performance enhancements:

- 27% increase in Li-ion battery cycle life (EV applications)

- 19% reduction in 5G base station thermal load

- 0.03mm ultra-thin coatings for flexible displays

Optimizing Mica Supply Chain Efficiency

The shift toward synthetic mica flakes addresses critical supply constraints while maintaining 92% of muscovite mica's beneficial properties. Strategic partnerships with ISO 9001-certified producers ensure 99.6% on-time delivery rates, supported by blockchain-enabled material tracking from mine to manufacturing.

(mica)

FAQS on mica

Q: What are synthetic mica flakes made of?

A: Synthetic mica flakes are lab-created using fluorophlogopite, a fluorine-rich mica variant. They mimic natural mica's layered structure but offer higher purity and consistency. These flakes are free from impurities often found in natural mica.

Q: Where is muscovite mica primarily mined?

A: Muscovite mica is predominantly found in India, Russia, Brazil, and the U.S. India's Jharkhand region is a major global supplier. It forms in metamorphic rocks like schist and granite pegmatites.

Q: What are common uses for muscovite mica?

A: Muscovite mica is used in electrical insulation, construction materials, and cosmetics. Its heat resistance makes it ideal for industrial equipment linings. It also adds shimmer to paints and beauty products.

Q: How does synthetic mica differ from natural muscovite?

A: Synthetic mica lacks trace metals present in natural muscovite, making it safer for cosmetics. It has superior thermal stability (up to 1200°C vs 700°C for natural). Production ensures uniform particle size and color.

Q: Why choose synthetic mica flakes over natural mica?

A: Synthetic flakes avoid ethical concerns linked to natural mica mining. They provide predictable performance in coatings and plastics. Their chemical stability suits high-tech applications like aerospace materials.

-

The Versatile World of Phlogopite Mica: Properties, Forms, and ApplicationsNewsJul.14,2025

-

The Versatile Applications of Calcined Mica: From Decoration to Industrial UseNewsJul.14,2025

-

The Role of Muscovite Mica in Industrial Insulation MaterialsNewsJul.14,2025

-

The Benefits of Using Expanded Clay Pebbles in Hydroponics and Soil GardeningNewsJul.14,2025

-

Innovative Applications of Mica Flake in Paints and CoatingsNewsJul.14,2025

-

Gardening Expanded Clay Usage: A Complete GuideNewsJul.14,2025

-

The Use of Natural Mica Powder in Skincare ProductsNewsJun.11,2025