The Strategic Role of Illite Powder in Advanced Paint Coatings

In the evolving landscape of industrial and architectural finishes, the demand for high-performance, sustainable, and cost-effective raw materials is paramount. Among these, Illite Powder for Paint Coatings stands out as a critical additive, revolutionizing the properties of various paint formulations. This natural clay mineral offers a unique blend of physical and chemical attributes that enhance paint durability, appearance, and application characteristics. Its distinctive lamellar structure and inherent inertness make it an ideal functional filler and extender, contributing to significant improvements in film integrity, anti-settling properties, and overall coating longevity. The strategic incorporation of illite powder reflects a growing industry trend towards maximizing performance while optimizing material usage and environmental impact in diverse sectors.

The global coatings market is continually seeking innovations that address challenges such as enhanced corrosion resistance, improved fire retardancy, and reduced volatile organic compound (VOC) emissions. Illite Powder for Paint Coatings directly contributes to these objectives by providing a stable, non-toxic, and highly functional additive. Its unique rheological properties can significantly reduce paint sagging, improve brushability, and enhance leveling, while its inherent hardness contributes to superior abrasion and scrub resistance of the dried film. Furthermore, the increasing focus on green building initiatives and sustainable manufacturing practices positions paint illite powder as a preferred choice, aligning with both stringent performance requirements and crucial environmental stewardship goals. Understanding its precise technical parameters and the rigor of its manufacturing process is crucial for paint formulators aiming to achieve superior product outcomes and competitive advantages.

Manufacturing Precision: The Illite Powder Production Process

The production of high-grade Illite Powder for Paint Coatings involves a sophisticated multi-stage process designed to ensure unparalleled consistency in quality, precise particle size distribution, and optimal purity. This meticulous approach is absolutely crucial for achieving the desired performance enhancements in complex paint formulations, where even subtle variations in raw material characteristics can significantly impact end-product attributes. Our manufacturing philosophy places a strong emphasis on utilizing advanced processing techniques, implementing stringent quality control protocols at every critical stage, and ensuring unwavering adherence to international industry standards such as ISO and ANSI for material specifications and rigorous testing procedures. The resulting product consistently exhibits superior dispersibility, exceptional chemical inertness, and precise rheological control, which are vital characteristics for demanding paint applications across a wide array of industries.

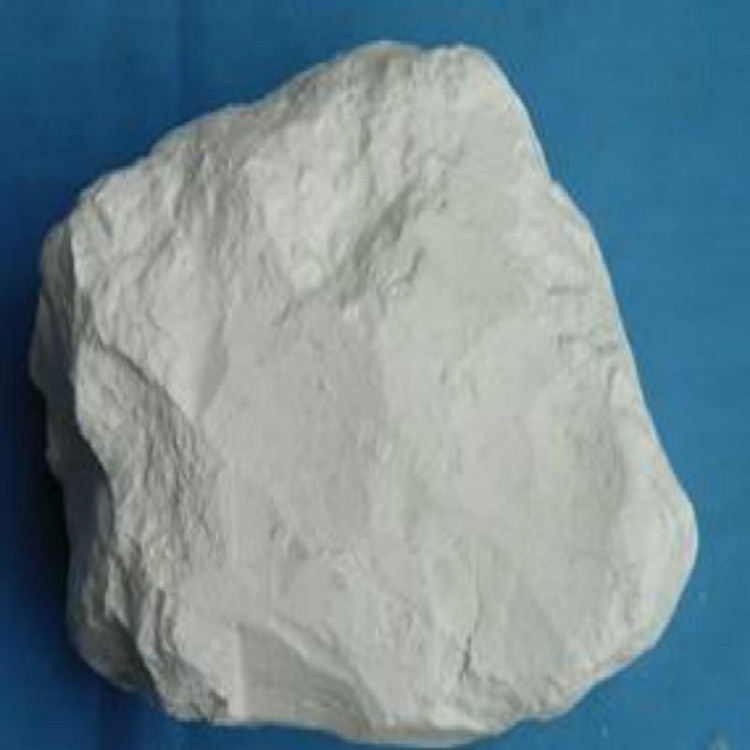

Refined Illite Powder for High-Performance Coatings

Key Stages of Illite Powder Manufacturing:

- Raw Material Sourcing & Pre-Treatment: High-purity illite ore is meticulously selected from geological deposits renowned for their mineralogical consistency and minimal impurities. Initial crushing reduces the ore to manageable sizes, followed by thorough washing and drying processes to effectively remove extraneous materials and moisture. This foundational step is critical for ensuring the inherent quality and performance attributes of the final paint illite powder.

- Primary Grinding & Classification: The pre-treated raw material undergoes primary grinding using advanced milling equipment, such as efficient Raymond mills or robust ball mills, to achieve a uniform coarse powder. This is immediately followed by a sophisticated air classification system that precisely separates particles based on their size, ensuring a tight and consistent particle size distribution tailored for specific paint applications and optimal dispersion.

- Ultra-Fine Milling & Surface Treatment (Optional): For specific high-end paint formulations requiring enhanced gloss or finer film appearance, the powder may undergo an additional stage of ultra-fine milling to achieve micron or sub-micron particle sizes. In certain applications, specialized surface treatments (e.g., with silanes or fatty acids) are applied to further enhance dispersibility, improve compatibility with various resin systems, and ultimately boost the performance of Illite Powder for Paint Coatings.

- Quality Control & Analysis: Throughout the entire manufacturing process, rigorous multi-point quality control checks are performed. This comprehensive analysis includes precise particle size analysis using laser diffraction, detailed chemical composition analysis via X-ray fluorescence (XRF), accurate measurements of whiteness and brightness, determination of oil absorption, and specific gravity tests. Every single batch must meet and often exceed strict internal specifications, as well as specific customer-defined requirements.

- Packaging & Dispatch: The finished illite powder is carefully packaged in moisture-resistant bags or bulk container111s, ensuring its intrinsic integrity and preventing contamination during storage and transportation. Proper, secure packaging is paramount to maintaining product quality and performance until it reaches the customer's facility, ready for immediate integration into their formulations.

This meticulous and technologically advanced production process ensures that our paint illite powder consistently delivers superior and reliable performance, making it an indispensable component for diverse coating formulations across critical industries such as petrochemical, metallurgy, and water treatment infrastructure. In these demanding sectors, exceptional longevity, robust corrosion resistance, and resilience to harsh environmental conditions are paramount. The precise ability to control particle geometry and surface chemistry allows for tailoring illite powder to extremely specific application needs, significantly enhancing properties like anti-corrosion performance and enabling tangible energy savings through optimized film thickness and reduced overall material consumption.

Technical Specifications and Performance Metrics

The efficacy of Illite Powder for Paint Coatings is quantified through a comprehensive range of technical parameters, each critically contributing to its unique functional properties within sophisticated paint and coating systems. Understanding these precise specifications is absolutely crucial for paint formulators to select the optimal illite grade for their specific application, thereby ensuring desired rheology, superior film strength, consistent opacity, and overall cost-effectiveness. Our rigorous testing protocols and adherence to international standards ensure that every batch consistently meets stringent quality benchmarks, providing unparalleled performance and reliability. The table below outlines typical and representative specifications for high-quality illite powder specifically engineered for advanced coating applications, demonstrating its superior characteristics.

| Parameter | Typical Value Range | Unit/Method | Benefit in Coatings |

|---|---|---|---|

| Purity (Illite Content) | > 90% | XRD Analysis | Ensures consistent performance, minimal impurities, enhanced functional properties |

| Average Particle Size (D50) | 3 - 15 µm | Laser Diffraction | Optimized film smoothness, opacity, consistent rheology, and anti-settling |

| Oil Absorption | 35 - 55 g/100g | ISO 787-5 | Balanced binder demand, aids matting effect, improves dispersion |

| Specific Gravity | 2.6 - 2.8 g/cm³ | ASTM D153 | Density consistency, superior anti-settling properties, weight control |

| Whiteness (R457) | > 80% | ISO 2470 | Excellent brightness, allows for reduced titanium dioxide usage, color stability |

| Mohs Hardness | 1.0 - 2.0 | Mohs Scale | Significantly improved scrub resistance, scratch resistance, and overall film toughness |

| pH Value (10% Slurry) | 6.5 - 8.0 | Electrode Method | Ensures chemical stability, broad compatibility with diverse binders and additives |

These meticulously controlled specifications demonstrate why paint illite powder is a preferred choice for discerning formulators across the globe. Its optimal particle size distribution is critical in achieving desired film thickness uniformity and exceptional surface smoothness without compromising crucial mechanical properties. The carefully controlled oil absorption characteristic directly contributes to efficient pigment dispersion, minimizes flocculation, and effectively prevents undesirable sagging or settling in stored paints. Furthermore, the inherent chemical inertness of illite guarantees long-term stability and outstanding compatibility with diverse binder systems, which is absolutely critical for both water-borne and solvent-borne coatings in various harsh environments. Such precise technical control and guaranteed specifications are the hallmarks of a reliable and leading supplier committed to delivering only the highest performance solutions to the paint and coatings industry.

Versatile Applications and Core Technical Advantages

The exceptional versatility of Illite Powder for Paint Coatings makes it an indispensable component across a wide and diverse spectrum of industries and application types. Its unique lamellar (platy) structure and inert chemical composition contribute significantly to improving various crucial coating properties, ranging from aesthetic appeal and functional performance to outstanding durability and protective capabilities. This advanced natural mineral filler offers multi-faceted and synergistic benefits, making it an exceptionally valuable and strategic component in the formulation of modern, high-performance paint systems. Its adaptability allows formulators to achieve specific performance targets, optimizing both quality and cost-efficiency.

Key Application Scenarios:

- Architectural Paints: Significantly enhances scrub resistance, measurably improves hiding power and opacity, and consistently provides a remarkably smooth, uniform, and aesthetically pleasing finish for both interior and exterior wall coatings. Its optimal rheological properties actively help prevent undesirable sagging and dramatically improve application properties like brushability and roller spread.

- Industrial Coatings: Extensively utilized in high-performance protective coatings for critical infrastructure such as heavy machinery, complex pipelines, and vital structural steel elements, offering exceptionally enhanced corrosion resistance and greatly improved mechanical strength, particularly in extremely harsh and aggressive industrial environments. Paint illite powder directly contributes to the extended longevity and significantly reduced maintenance requirements of these crucial industrial assets.

- Automotive Finishes: Plays a vital role in contributing to vastly improved scratch resistance, superior chip resistance, and excellent gloss retention in both automotive primers and critical topcoats, thereby ensuring an exceptionally durable and aesthetically appealing finish that withstands the rigors of daily use and environmental exposure.

- Road Marking Paints: Dramatically enhances durability, improves critical reflectivity, and strengthens adhesion to various road surfaces, allowing the coatings to withstand intense heavy traffic, extreme abrasion, and diverse adverse weather conditions, ensuring long-lasting visibility and safety.

- Wood Coatings: Provides excellent sanding properties, greatly improved hardness, and exceptional clarity for lacquers and varnishes, which are absolutely crucial characteristics for high-quality furniture, intricate cabinetry, and durable flooring applications, ensuring both protection and beauty.

Diverse Applications of Illite Powder in Coatings

Core Technical Advantages:

- Rheology Modification: Acts as an exceptionally effective rheological additive, precisely controlling viscosity, actively preventing pigment settling, and significantly improving critical application properties such as sag resistance, leveling, and flow characteristics. This optimizes the consistency and ease of application of Illite Powder for Paint Coatings.

- Enhanced Film Integrity & Durability: The distinct platy structure of illite creates an incredibly tortuous path for moisture penetration and corrosive agents, leading to a significant improvement in barrier properties, superior anti-corrosion performance, and vastly enhanced overall film integrity. This directly contributes to a substantially longer coating lifespan and reduced maintenance cycles.

- Improved Mechanical Properties: Consistently increases the inherent hardness, drastically improves scratch resistance, and significantly boosts the abrasion resistance of the dried paint film, thereby considerably extending the service life and maintaining the aesthetic appeal of coated surfaces even under heavy wear.

- UV Stability & Weatherability: As a naturally inert mineral, illite contributes directly to enhanced UV stability and superior overall weather resistance of the coating, which is an absolutely crucial factor for long-term performance and color retention in exterior coating applications exposed to harsh elements.

- Cost-Effectiveness & Opacity: As a highly effective functional extender, it facilitates the partial replacement of more expensive primary pigments (such as titanium dioxide, TiO2) while maintaining or even demonstrably improving opacity and hiding power. This leads to significant material cost savings without compromising visual or protective performance.

- Eco-Friendly Profile: Being a natural, non-toxic, and chemically inert mineral, illite powder is an inherently sustainable and environmentally responsible choice for formulating low VOC (Volatile Organic Compound) and other ecologically conscious paint products, aligning with global green chemistry initiatives.

The strategic integration of paint illite powder into sophisticated paint formulations represents a critically sound decision for manufacturers seeking to deliver superior performance characteristics without any compromise on either sustainability objectives or essential cost efficiency. Its proven benefits and consistent performance in numerous real-world application cases powerfully highlight its indispensable and ever-growing role in the dynamic and technologically advanced modern coatings industry, setting new benchmarks for quality and longevity.

Customization Solutions and Unrivaled Customer Support

Recognizing the increasingly diverse and often highly specialized requirements of the global coatings industry, a truly leading supplier of Illite Powder for Paint Coatings must offer comprehensive and highly flexible customization solutions. This tailored approach is paramount to ensuring that paint manufacturers receive products precisely aligned with their unique and specific formulation needs, whether that entails a particular and exact particle size distribution, a specialized surface treatment for enhanced compatibility, or a specific level of chemical purity for sensitive applications. Our dedicated technical team actively works in close collaboration with clients, engaging deeply to understand their specific challenges and develop bespoke illite powder solutions that not only optimize product performance but also significantly reduce production costs and accelerate time-to-market for their innovative coating products.

Our Customization Capabilities Include:

- Precision Particle Size Engineering: Utilizing advanced grinding and classification technologies to achieve desired D50, D90, or precise top-cut specifications, crucial for specific gloss levels, film thickness, and rheology control.

- Tailored Surface Modification: Expert application of various coupling agents or specialized surface treatments to significantly enhance compatibility with a wide range of specific resin systems (e.g., epoxy, acrylic, alkyd, polyurethane) and dramatically improve dispersion characteristics within complex formulations.

- Purity and Whiteness Optimization: Fine-tuning our sophisticated processing methods to achieve specific, client-requested levels of mineral purity and brightness, which is critical for color-sensitive applications where consistent hue and luminosity are paramount.

- Development of Specialized Grades: Focused research and development of unique illite powder grades specifically engineered for niche applications that require particular rheological properties, enhanced barrier performance against aggressive chemicals, or superior abrasion resistance under extreme conditions.

Beyond our unparalleled product customization capabilities, our unwavering commitment extends to providing unrivaled and proactive customer support throughout the entire engagement lifecycle. We firmly understand that purchasing high-quality raw materials is merely the initial step; ongoing technical assistance, reliable and efficient logistics, and transparent, open communication are equally vital for our clients' operational success and peace of mind.

Our Commitment to Trustworthiness and Client Success:

- Transparent Delivery Cycle: We provide clear, predictable, and consistently updated delivery schedules, leveraging highly efficient global logistics networks to ensure the timely arrival of your paint illite powder, thereby minimizing potential supply chain disruptions and ensuring operational continuity for your business.

- Comprehensive Quality Assurance: Every single batch of illite powder produced undergoes rigorous, multi-point testing in our state-of-the-art, ISO 9001 certified laboratories. We provide comprehensive and detailed Certificates of Analysis (CoA) for each and every shipment, unequivocally guaranteeing strict adherence to agreed-upon specifications and all relevant international industry standards. Our robust quality management system meticulously covers all aspects, from raw material intake to final product release and dispatch.

- Robust Warranty and Proactive Customer Support: We proudly stand behind the exceptional quality of our products with a clear, industry-leading warranty policy. Our dedicated and highly experienced technical support team is readily available to assist with complex formulation challenges, expertly troubleshoot any application issues, and provide invaluable expert guidance on maximizing the benefits and performance potential of Illite Powder for Paint Coatings in your specific systems. Crucially, client feedback is actively and continuously sought, then systematically integrated into our continuous improvement processes, ensuring we always meet and exceed evolving industry demands.

- Proven Application Cases & Client Success Stories: Our extensive and growing portfolio includes numerous successful partnerships with leading paint manufacturers globally. These tangible application cases vividly demonstrate the significant and measurable benefits achieved by our valued clients, such as vastly enhanced coating durability in extreme climatic conditions, remarkably improved cost-efficiency in large-scale production, and the successful development of cutting-edge, innovative, and environmentally friendly paint products that meet stringent regulatory requirements.

This holistic approach, which seamlessly combines expert product development and advanced customization with steadfast logistical reliability and proactive technical support, robustly solidifies our position as a most trusted and preferred partner in the demanding B2B coatings sector. We are not merely suppliers of raw materials; we are dedicated solution providers, deeply committed to your long-term success and innovation in the coatings industry.

Frequently Asked Questions (FAQs) about Illite Powder for Paint Coatings

Q1: What is the primary benefit of using illite powder compared to other mineral fillers in paint coatings?

A1: Illite Powder for Paint Coatings offers a unique combination of superior advantages, primarily due to its distinct platy (lamellar) structure. This structure significantly enhances the film's barrier properties against moisture penetration and aggressive chemicals, greatly improves mechanical strength including outstanding scrub and abrasion resistance, and provides precise rheology control to effectively prevent undesirable pigment settling and paint sagging during application and storage. Crucially, unlike some other common mineral fillers, illite is inherently chemically inert, ensuring long-term stability and broad compatibility with diverse paint binder systems, while also contributing meaningfully to overall cost-effectiveness through its functional extender properties.

Q2: Can illite powder be effectively used in both water-based and solvent-based paint systems?

A2: Yes, indeed. High-quality paint illite powder is engineered for broad compatibility and can be seamlessly and effectively integrated into both water-based and solvent-based paint systems. Its inherent inert nature, coupled with the capability to apply specific surface treatments, allows for excellent dispersion and ensures consistent, superior performance across a wide array of resin chemistries and formulation types. This exceptional versatility makes it a highly adaptable and invaluable additive for developing modern, high-performance paint and coating formulations that meet diverse industry needs.

Q3: How does illite powder specifically contribute to the sustainability of paint products?

A3: As a naturally occurring and abundantly available mineral, illite powder is an inherently sustainable and environmentally responsible choice for paint formulations. Its strategic use can significantly reduce the overall reliance on, and the need for, more energy-intensive synthetic materials and pigments, thereby lowering the carbon footprint of the final product. Furthermore, by substantially improving paint durability, adhesion, and overall lifespan, it directly contributes to less frequent repainting cycles, resulting in significant savings of raw materials, energy resources, and a substantial reduction in waste generation. Its non-toxic profile also actively supports the development of low VOC (Volatile Organic Compound) and other environmentally conscious coating solutions, aligning perfectly with global sustainability initiatives and stricter regulatory requirements.

Q4: What are the recommended storage conditions for illite powder to maintain its optimal quality?

A4: To maintain the optimal quality, functional properties, and performance characteristics, Illite Powder for Paint Coatings should be stored in a cool, exceptionally dry place, ideally within its original, securely sealed packaging. It is critically important to protect the product from direct exposure to sunlight, high humidity, and extreme temperature fluctuations, as these conditions can lead to moisture absorption or caking, which may adversely affect its physical properties and subsequently impact ease of dispersion and overall performance during the paint formulation process. Proper storage ensures consistent product quality and maximizes shelf life.

Authoritative References and Further Reading

The information presented herein is meticulously based on extensive industry knowledge, rigorous laboratory testing, and established scientific principles within the fields of materials science and advanced coatings technology. For those interested in delving deeper into the profound scientific and technical aspects of illite and its multifaceted applications in protective and decorative coatings, the following authoritative references provide invaluable insights from respected academic and industry-leading sources:

- Bergaya, F., & Lagaly, G. (Eds.). (2006). Handbook of Clay Science. Elsevier.

- Wicks, Z. W., Jones, F. N., Pappas, S. P., & Wicks, D. A. (2007). Organic Coatings: Science and Technology (3rd ed.). John Wiley & Sons.

- American Society for Testing and Materials (ASTM) International. Standards for Pigments and Coatings. (Ongoing publications).

- International Organization for Standardization (ISO). Standards for Paints and Varnishes. (Ongoing publications).

- Smith, B. (2018). The Role of Lamellar Fillers in Enhancing Barrier Properties of Polymeric Coatings. Journal of Coatings Technology and Research, 15(4), 819-830.

-

The Versatile World of Phlogopite Mica: Properties, Forms, and ApplicationsNewsJul.14,2025

-

The Versatile Applications of Calcined Mica: From Decoration to Industrial UseNewsJul.14,2025

-

The Role of Muscovite Mica in Industrial Insulation MaterialsNewsJul.14,2025

-

The Benefits of Using Expanded Clay Pebbles in Hydroponics and Soil GardeningNewsJul.14,2025

-

Innovative Applications of Mica Flake in Paints and CoatingsNewsJul.14,2025

-

Gardening Expanded Clay Usage: A Complete GuideNewsJul.14,2025

-

The Use of Natural Mica Powder in Skincare ProductsNewsJun.11,2025