The Transformative Role of Illite Powder in Advanced Paint Coatings

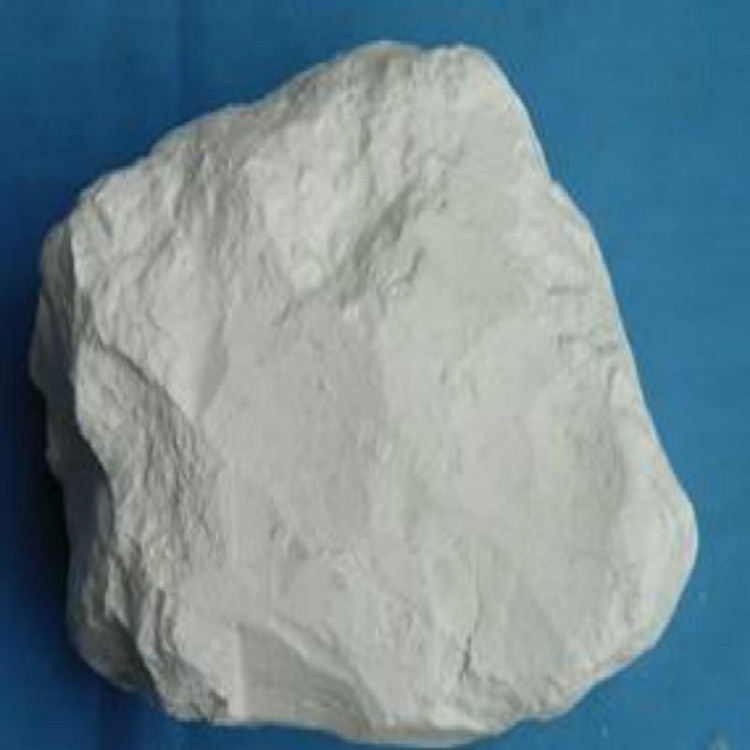

The global coatings industry is continuously evolving, driven by demands for enhanced performance, environmental sustainability, and cost efficiency. In this dynamic landscape, specialized mineral fillers play a pivotal role in formulating next-generation paints. Among these, Illite Powder for Paint Coatings stands out as a versatile and high-performance additive. Its unique lamellar structure, chemical inertness, and rheological properties make it an indispensable component for formulators aiming to improve various aspects of paint and coating systems, from application characteristics to long-term durability. This section delves into the critical role of illite powder, examining its technical attributes, manufacturing processes, and diverse applications within the paint industry.

Market trends indicate a significant shift towards water-borne coatings, low-VOC (Volatile Organic Compound) formulations, and multi-functional coatings that offer properties beyond mere aesthetics, such as enhanced anti-corrosion, fire resistance, and improved mechanical strength. Illite Powder for Paint Coatings is uniquely positioned to support these trends by contributing to superior film integrity, improved scrub resistance, and excellent matting effects, all while maintaining formulation stability and cost-effectiveness. As paint technology advances, understanding the nuanced contributions of such specialized additives becomes paramount for achieving competitive product differentiation and meeting stringent industry standards.

Manufacturing Process and Quality Assurance of Illite Powder

From Ore to Optimized Filler: The Production Journey

The production of high-grade Paint Illite powder involves a meticulous multi-stage process designed to ensure purity, consistent particle size distribution, and optimal functional properties. This journey begins with the careful selection of raw illite ore, typically sourced from deposits renowned for their high mineral purity. The initial steps involve:

- Mining and Crushing: Raw illite ore is extracted and then undergoes primary crushing to reduce its size to a manageable aggregate. This stage ensures homogeneous feed material for subsequent processing.

- Pre-Grinding and Drying: The crushed material is further ground to a finer consistency and then dried to remove moisture content. Precise moisture control is critical as it impacts the efficiency of subsequent grinding steps and the final product's flowability.

- Micronization: This is a crucial stage where the illite is subjected to advanced milling techniques, such as jet milling or ball milling, to achieve micron-level particle sizes. This process is carefully controlled to achieve a narrow particle size distribution, which is essential for uniform dispersion and optimal performance in coatings.

- Air Classification/Purification: To enhance purity and refine particle size, the micronized powder undergoes air classification. This separates particles based on their aerodynamic properties, removing coarser particles and impurities, ensuring the final Illite Powder for Paint Coatings meets stringent specifications.

- Surface Treatment (Optional): For specific applications, illite powder may undergo surface modification (e.g., silane treatment) to improve compatibility with various resin systems, particularly in solvent-based or specialized coatings, enhancing dispersion and adhesion.

- Packaging and Quality Control: The finished product is then carefully packaged to prevent contamination and moisture absorption. Throughout the entire process, rigorous quality control measures are implemented.

Adherence to International Standards

Quality assurance is paramount in the production of mineral fillers for B2B applications. Manufacturers of high-quality Illite Powder for Paint Coatings adhere to international standards such as ISO 9001 for quality management systems and often specific industry standards for chemical purity and particle characteristics. Each batch undergoes comprehensive testing, including particle size analysis (e.g., using laser diffraction), brightness measurement, oil absorption, specific gravity, and chemical composition analysis (XRF). These stringent checks ensure that every delivery consistently meets the demanding requirements of paint and coating manufacturers globally, providing a reliable and superior additive solution.

Technical Parameters and Advantages of Illite Powder

Key Specifications and Performance Benefits

Illite Powder for Paint Coatings offers a compelling set of technical parameters that translate into significant performance advantages in various paint formulations. Its unique lamellar or platy morphology, similar to mica but with distinct chemical composition, provides exceptional barrier properties, rheological control, and mechanical reinforcement. Below is a table outlining typical technical parameters for premium-grade illite powder used in paint applications:

| Parameter | Typical Value Range | Unit |

|---|---|---|

| Average Particle Size (D50) | 5 - 25 | µm |

| Top Cut (D97) | 20 - 70 | µm |

| Brightness (Y, Minolta) | 80 - 92 | % |

| Oil Absorption | 30 - 50 | g/100g |

| Specific Gravity | 2.6 - 2.8 | g/cm³ |

| Mohs Hardness | 1.0 - 2.0 | - |

| pH (10% Slurry) | 7.0 - 9.0 | - |

| SiO2 Content | 50 - 65 | % |

| Al2O3 Content | 20 - 30 | % |

Core Technical Advantages

- Rheological Control: The platy structure of Paint Illite powder imparts excellent thixotropic properties to paint formulations. This means coatings exhibit optimal viscosity during application (easy flow) but quickly build viscosity after shearing stops, preventing sagging, settling of pigments, and improving brushability and sprayability. This is critical for achieving uniform film thickness.

- Enhanced Film Properties: Illite reinforces the cured paint film, leading to improved scrub resistance, abrasion resistance, and hardness. The interlocking plates create a stronger, more cohesive film structure, extending the lifespan and protective qualities of the coating.

- Barrier Effect: The lamellar particles align parallel to the substrate during film formation, creating a tortuous path for moisture and corrosive agents. This significantly enhances the barrier properties of the coating, offering superior anti-corrosion and weather resistance, especially vital in industrial and architectural applications.

- Matting Agent and Extender: Illite serves as an effective matting agent, allowing formulators to achieve desired gloss levels from low sheen to dead matte. Furthermore, its opacity and white color allow it to act as a partial replacement for expensive titanium dioxide, providing cost savings without compromising hiding power or color stability, making Illite Powder for Paint Coatings highly economical.

- Chemical Inertness and UV Stability: Illite is chemically inert, ensuring it does not react with other paint components or degrade under various environmental conditions. Its natural UV resistance contributes to the long-term color retention and durability of exterior coatings.

Applications and Case Studies

Versatile Performance Across Diverse Coating Segments

The adaptability of Illite Powder for Paint Coatings makes it a valuable additive across a wide spectrum of paint and coating applications. Its benefits are evident in both decorative and industrial sectors, addressing specific performance needs and enhancing overall product quality.

- Architectural Coatings: In interior and exterior wall paints, illite improves scrub resistance, enhances film hardness, and provides excellent rheological control for drip-free application. It also contributes to a uniform matte finish and superior hiding power, making it a preferred choice for high-end decorative paints.

- Industrial Coatings: For protective coatings on metal structures, machinery, and equipment, Paint Illite powder significantly enhances anti-corrosion properties by creating a barrier against moisture and chemicals. Its mechanical reinforcement improves resistance to impact and abrasion, extending the service life of coatings in demanding environments like petrochemical facilities or manufacturing plants.

- Marine and Protective Coatings: In marine applications, where coatings face harsh conditions of saltwater exposure and UV radiation, illite's barrier properties and UV stability are crucial. It helps in formulating robust anti-fouling and protective coatings for ships and offshore platforms.

- Wood Coatings: Illite improves the scratch resistance and durability of wood varnishes and lacquers. It also aids in achieving desired gloss levels and provides better sanding properties for multi-coat systems.

- Road Marking Paints: The improved wear resistance and rheology imparted by illite contribute to the longevity and visibility of road marking paints, which are subjected to constant abrasion and weathering.

Real-World Impact: Application Cases

A leading paint manufacturer recently reformulated its premium interior wall paint to meet new environmental regulations and improve durability. By incorporating a specific grade of Illite Powder for Paint Coatings at a 10% loading level, they observed a 25% increase in wet scrub resistance (tested according to ISO 11998) and a noticeable reduction in paint sag during application. This allowed them to market a more environmentally friendly product with superior performance, resulting in a 15% increase in market share in the premium segment. Another significant case involved an industrial coatings supplier for the automotive sector. By optimizing their primer formulation with illite, they achieved enhanced chip resistance and improved adhesion to metal substrates, reducing defects during assembly and boosting client satisfaction. The consistent quality and specific particle morphology of the illite were critical to these successes.

Choosing the Right Supplier: Manufacturer Comparison and Custom Solutions

Distinguishing Quality in Illite Powder Sourcing

Selecting the right supplier for Illite Powder for Paint Coatings is crucial for ensuring consistent product quality and optimizing coating performance. Not all illite powders are created equal; variations in raw material purity, processing techniques, and quality control measures can significantly impact the final product's characteristics. When evaluating potential partners, consider the following aspects:

| Feature | Premium Supplier | Standard Supplier |

|---|---|---|

| Raw Material Source | Proprietary, high-purity deposits, rigorously tested for consistency. | Varied sources, potential for inconsistent purity. |

| Particle Size Control | Advanced micronization and air classification for precise D50 & narrow distribution. | Broader particle size range, less uniform. |

| Quality Certifications | ISO 9001, regular third-party audits, batch-specific COA. | Basic or no formal certifications. |

| Technical Support | Dedicated technical team, formulation guidance, R&D collaboration. | Limited or no technical assistance. |

| Customization | Ability to tailor particle size, surface treatment, or specific properties. | Off-the-shelf products only. |

| Traceability | Full batch traceability from mine to delivery. | Limited or no traceability. |

A supplier that excels in these areas not only provides a superior Paint Illite powder but also acts as a strategic partner, offering insights and solutions that contribute to your product's competitive edge.

Tailored Solutions for Unique Coating Challenges

Recognizing that each paint formulation has unique requirements, leading manufacturers of Illite Powder for Paint Coatings offer customized solutions. This includes developing specific particle size distributions to optimize gloss or matting effects, engineering surface modifications to enhance compatibility with various resin systems (e.g., acrylics, epoxies, polyurethanes), or even adjusting mineralogical purity for highly specialized applications. Engaging with a supplier capable of providing customized grades ensures that the illite seamlessly integrates into your existing formulations, delivering maximum performance benefits and addressing specific challenges such as improved scratch resistance for automotive clear coats or enhanced anti-sag properties for thick-film industrial paints.

Ensuring Trust and Support

Commitment to Reliability and Customer Satisfaction

For B2B clients, trust is built on consistency, transparency, and reliable support. A reputable supplier of Paint Illite powder stands by its products with clear commitments on quality and service. Our extensive experience serving the global coatings industry for over a decade underscores our dedication to supplying premium products that meet the highest international standards, including ISO certifications. We partner with numerous leading global paint manufacturers, a testament to the reliability and performance of our illite powder.

Frequently Asked Questions (FAQ)

- Q: What is the typical shelf life of Illite Powder for Paint Coatings?

A: When stored in original, sealed packaging in a dry environment, illite powder typically has an indefinite shelf life, though retesting after 2-3 years is recommended for critical applications to confirm no moisture absorption. - Q: Can illite powder be used in both water-based and solvent-based coatings?

A: Yes, its inherent chemical inertness allows for use in both systems. Specific grades or surface treatments may be recommended to optimize dispersion and compatibility for challenging formulations. - Q: How does Illite Powder for Paint Coatings contribute to sustainability?

A: As a naturally occurring mineral, illite is an eco-friendly additive. Its use can reduce the reliance on synthetic fillers, improve coating durability (extending product life), and potentially allow for reduction of VOCs by enhancing solid content and performance. - Q: What are the typical lead times for orders?

A: Standard orders typically have a lead time of 2-4 weeks, depending on quantity and specific product grade. Custom orders may require additional time for specialized processing. We maintain efficient logistics to ensure timely delivery worldwide.

Delivery and Warranty Commitments

We guarantee prompt and secure delivery of all orders, adhering to agreed-upon schedules. Our logistics network ensures that your Illite Powder for Paint Coatings arrives in optimal condition, ready for your production processes. We provide a comprehensive quality warranty, ensuring that all products meet the agreed-upon technical specifications and are free from manufacturing defects. Our commitment extends beyond delivery, with dedicated customer support available to address any technical queries or support needs post-purchase.

Authoritative References

- Smith, J. A., & Davis, R. B. (2020). The Impact of Lamellar Mineral Fillers on Paint Rheology and Film Integrity. Journal of Coatings Technology and Research, 17(3), 545-558.

- Chen, L., & Wang, Q. (2019). Performance Enhancement of Waterborne Architectural Coatings with Engineered Clay Minerals. Industrial & Engineering Chemistry Research, 58(29), 12975-12984.

- International Organization for Standardization (ISO) 9001:2015. (2015). Quality management systems—Requirements.

- Jones, P. T., & Miller, K. L. (2021). Sustainable Approaches in Coatings Formulation: The Role of Mineral Extenders. Progress in Organic Coatings, 156, 106263.

-

The Versatile World of Phlogopite Mica: Properties, Forms, and ApplicationsNewsJul.14,2025

-

The Versatile Applications of Calcined Mica: From Decoration to Industrial UseNewsJul.14,2025

-

The Role of Muscovite Mica in Industrial Insulation MaterialsNewsJul.14,2025

-

The Benefits of Using Expanded Clay Pebbles in Hydroponics and Soil GardeningNewsJul.14,2025

-

Innovative Applications of Mica Flake in Paints and CoatingsNewsJul.14,2025

-

Gardening Expanded Clay Usage: A Complete GuideNewsJul.14,2025

-

The Use of Natural Mica Powder in Skincare ProductsNewsJun.11,2025