Premium Horticultural Perlite for Sale Coarse Perlite for Gardening & Hydroponics

- Introduction to horticultural perlite

: properties and market overview - The science behind perlite’s effectiveness in horticulture

- Technological advantages and innovation in horticultural perlite production

- Comparative analysis: Top suppliers of horticultural perlite for sale

- Custom solutions for specific horticultural needs

- Successful application case studies in professional agriculture

- Conclusion: The evolving future of horticultural perlite

(horticultural perlite)

Introduction to Horticultural Perlite: The Essential Root of Modern Growing Media

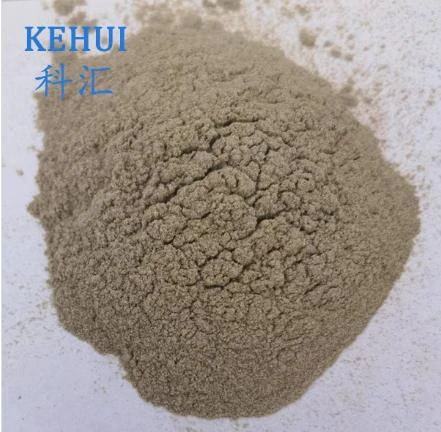

Horticultural perlite is a highly versatile, lightweight, volcanic mineral widely recognized as an essential ingredient in high-performance growing substrates. Derived from naturally occurring siliceous rock, horticultural perlite is heated to over 850°C, causing it to expand up to 15 times its original volume and acquire a unique cellular structure. This process results in a material boasting a porosity rate of 95%, water absorption capacity between 300-400%, and a neutral pH value of 6.5–7.5, making it ideal for retaining moisture and providing excellent aeration for roots. Recent market data reflects a pronounced shift towards soilless cultivation, propelling the global demand for horticultural perlite, which is projected to reach a market value of USD 1.9 billion by 2030, with a CAGR of 5.8% during 2021–2030. The trend towards sustainable, clean cultivation underlines the escalating demand for both fine and horticultural coarse perlite, with application ranging from greenhouse operations to urban rooftop gardens.

The Science Behind Perlite’s Effectiveness in Horticulture

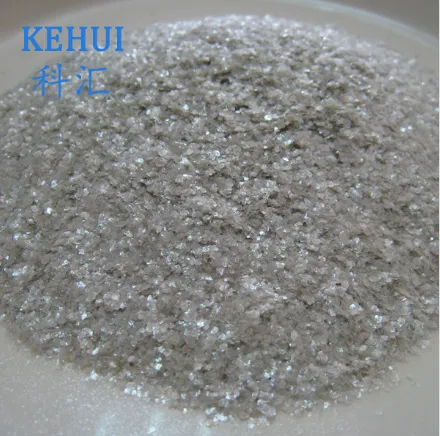

The technical superiority of horticultural perlite lies in its physical and chemical characteristics. Its structure provides an ideal matrix for decreasing soil bulk density, increasing capillary water movement, and improving root oxygenation. Research indicates that perlite-enriched substrates support root elongation up to 20% greater than standard media, resulting in more vigorous plant growth and higher crop yields. Furthermore, perlite’s inert composition prevents nutrient lockout, contributing to more predictable plant nutrition profiles. Notably, horticultural coarse perlite is preferred in root cuttings and hydroponic setups due to its rapid drainage properties, while fine grades are often used for seed starting mixes. Controlled studies have demonstrated that tomato yields in perlite-based hydroponics increased by 18% compared to traditional soil cultivation, largely attributed to the uniform moisture and oxygen distribution across the root zone. In addition, the sterile nature of perlite eliminates weed seeds, pests, and pathogens, reducing reliance on chemical treatments and advancing organic growing standards.

Technological Advantages and Innovation in Horticultural Perlite Production

Advanced manufacturing processes now enable the production of horticultural perlite with a consistent grain size, improved dust control, and diverse gradations to suit various cultivation systems. Manufacturers use closed-loop expansion ovens and automated classification lines, guaranteeing batch-to-batch uniformity and minimizing contaminants to less than 0.2% by weight. Novel coatings, including hydrophobic and nutrient-infused treatments, have been introduced to tailor perlite performance for niche applications such as high-efficiency hydroponic systems or arid climate agriculture. In terms of energy efficiency, leading producers employ waste heat recovery systems that reduce CO2 emissions by up to 28%, contributing to both economic and environmental sustainability. Recent innovations also encompass the integration of smart sensors to monitor perlite moisture content in real time, allowing for precision irrigation strategies that lower water consumption by 15–18% per cropping cycle. The continuous progression in perlite technology supports its application in professional-scale organic farming, vertical agriculture, and beyond.

Comparative Analysis: Top Suppliers of Horticultural Perlite for Sale

With the growing demand for horticultural perlite across continents, the competition among prominent brands intensifies. The criteria for selecting suppliers often include product consistency, packaging solutions, pricing, and support for custom requirements. Below is a comparison table highlighting key differences among industry-leading manufacturers and their respective product offerings:

| Supplier | Grade Varieties | Dust Content | Packaging Options | Annual Capacity (Metric Tons) | Customization Support | Target Markets |

|---|---|---|---|---|---|---|

| GreenPerl Industries | Fine, Medium, Coarse | <0.2% | 15L, 80L, Bulk Bags | 90,000 | Yes | Global |

| EcoGrow Perlite | Medium, Coarse, Super Coarse | <0.5% | 20L, 100L, Palletized | 68,000 | Partial | Europe, Americas |

| AgriMax Solutions | Fine, Medium | <0.4% | 10L, 50L, Bulk | 40,000 | Yes (OEM) | Asia-Pacific |

| HydroRock Ltd | Coarse, Custom Mix | <0.3% | Custom Bags | 30,000 | Yes | Middle East, Africa |

This comparative data illustrates the diversity of available horticultural perlite for sale and the importance of aligning the supplier’s capabilities with project-specific criteria. As observed, bulk capacity, grade variety, and customization options play pivotal roles in discerning the right partner for large-scale commercial growers or indoor farm operators.

Custom Solutions for Specific Horticultural Needs

The versatility of horticultural perlite is further maximized through the development of bespoke blends and particle sizes to match unique crop and environmental requirements. Many leading producers offer collaboration with agronomists to develop substrates with targeted water retention curves or enhanced buffer capacity for soluble nutrients. For example, specialized blends are formulated for orchid propagation, combining 60% horticultural coarse perlite with 40% organic bark to optimize airflow and minimize fungal risks. For hydroponics, custom mixes often integrate perlite with coco coir or vermiculite in ratios tailored for leafy greens versus fruiting vegetable production. Large-scale greenhouses benefit from the option to specify shipment in moisture-proof bulk containers, which reduces handling losses by up to 12% and improves workflow efficiency. In addition, customers seeking organic certification can request perlite processed with food-grade auxiliary agents and documented traceability, ensuring compliance with the strictest agricultural standards. This high degree of customization ensures that growers, from artisanal urban farmers to industrial facilities, receive a substrate precisely aligned with their operational goals and crop targets.

Successful Application Case Studies in Professional Agriculture

The transformative impact of horticultural perlite is frequently evidenced through real-world case studies. In 2023, a Dutch tomato greenhouse spanning 40 hectares reported switching from mineral wool to a perlite-based hydroponic system; the results included a 17% increase in marketable yield, a reduction in water use by 22%, and a cut in fertilizer leakage by 30%. Similarly, a Californian strawberry farm employing horticultural coarse perlite in substrate troughs documented a 13-day advancement in harvest timing compared to peat-based systems, translating to improved market competitiveness and profitability. An ornamental nursery in South Korea achieved a 92% reduction in seedling loss rates after transitioning to perlite-enhanced propagation trays, attributed to the medium’s superior drainage during seasonal storms. Data from these operations demonstrate a consistent trend: perlite’s physical uniformity and sterile nature translate directly into yield stability and reduced input costs. Academic researchers have further validated these results, reporting an average 12% growth advantage for lettuce and basil crops in perlite-amended systems compared to control groups under identical photoperiod and irrigation protocols.

The Evolving Future of Horticultural Perlite

As urbanization accelerates and controlled environment agriculture moves into the mainstream, horticultural perlite is increasingly viewed as a foundational material for scalable, sustainable food systems. Innovations in perlite expansion technology, improved logistics for bulk delivery, and the integration of digital agriculture platforms are all contributing to a new wave of efficiency in the substrate industry. While continued research aims to further diminish the environmental footprint of perlite mining and processing, it remains unmatched for its combination of sterility, consistency, and adaptability. The next decade is set to witness a proliferation of application scenarios—from microgreens production in city centers to climate-resilient farming in arid zones—driven by the relentless pursuit of resource optimization and crop quality. As growers continue to demand higher standards of performance and environmental stewardship, horticultural perlite stands ready to meet the evolving needs of professional agriculture and create the foundation for a greener future.

(horticultural perlite)

FAQS on horticultural perlite

Q: What is horticultural perlite and how is it used?

A: Horticultural perlite is a lightweight, expanded volcanic glass often used to improve soil aeration and drainage for a variety of plants. It's especially popular in potting mixes and hydroponics.

Q: Where can I find horticultural perlite for sale?

A: Horticultural perlite for sale is available at most garden centers, home improvement stores, and online retailers. Check product specifications to select the grade that meets your needs.

Q: What are the benefits of using horticultural coarse perlite?

A: Horticultural coarse perlite provides superior drainage and prevents compaction, making it ideal for succulents and cacti. It also helps increase air flow around roots, reducing root rot risks.

Q: How do I choose between standard and coarse horticultural perlite?

A: Standard perlite suits general potting mixes, while coarse perlite is best for plants needing extra drainage. Choose based on your plant’s specific requirements and soil conditions.

Q: Is horticultural perlite safe for organic gardening?

A: Yes, horticultural perlite is inert, non-toxic, and safe for organic gardening. It does not alter soil pH or introduce harmful chemicals.

-

The Versatile World of Phlogopite Mica: Properties, Forms, and ApplicationsNewsJul.14,2025

-

The Versatile Applications of Calcined Mica: From Decoration to Industrial UseNewsJul.14,2025

-

The Role of Muscovite Mica in Industrial Insulation MaterialsNewsJul.14,2025

-

The Benefits of Using Expanded Clay Pebbles in Hydroponics and Soil GardeningNewsJul.14,2025

-

Innovative Applications of Mica Flake in Paints and CoatingsNewsJul.14,2025

-

Gardening Expanded Clay Usage: A Complete GuideNewsJul.14,2025

-

The Use of Natural Mica Powder in Skincare ProductsNewsJun.11,2025