Aluminosilicate microspheres (cenospheres light fraction of fly ash, bottom ash microspheres , microspheres energy ashes) are hollow beads with a size range of 20-500 microns (most often, 100 – 250 microns) and a by-product of coal burning power plants.

Compared to irregular-shaped and partially-spherical fillers, the 100% spherical shape of Ceramic Microspheres, provides improved processing and performance.Being inert it is not affected by solvents, water, acids or alkalis. They are 75% lighter than other minerals currently used as a filler or extender.

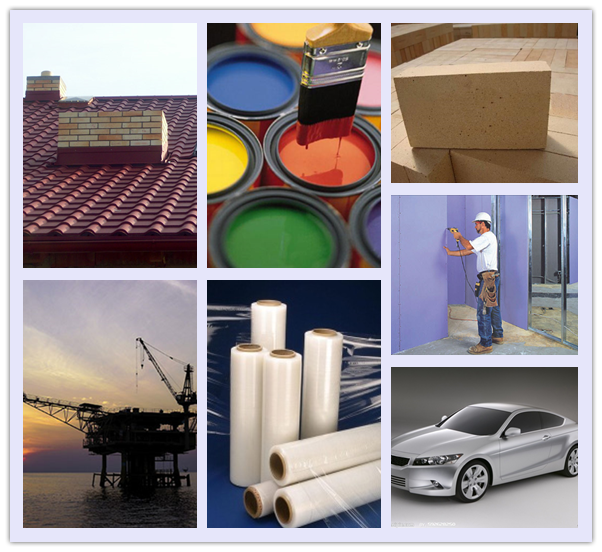

The unique combination of qualities of this product as an almost ideal spherical shape, low bulk density, high mechanical strength, thermal stability and chemical inertness, provided a wide range of applications as below:

1.Construction:ultra-light concrete, insulating plaster and masonry mortars, and other types of dry mixes, heat and sound insulation cover at the device roofing and facade structures, floors, as well as the preparation of thermal insulation for floors.

2.Paints Coating: Cenospheres are special additives that both chemists and formulators in the paints and coatings industry are using to enhance their products. A sphere has the lowest surface area of any shape.As a result, these hollow ceramic microspheres reduce resin demand and increase volume loading capacity.

3.Oil Field: oil well cements, drilling muds, grinding materials, explosives.

Cenospheres have been used in oilfield cementing for quite some time. During a cementing job, Cenospheres act to decrease the slurry density without increasing the water content. This in turn provides better compressive strength to the cement.

4.Ceramics: Refractories, Castables, Tile, Fire Bricks, Aluminium Cement, Insulating materials, Coatings.

5.Plastics: Cenospheres are an excellent lightweight filler for plastics and continue to grow in popularity and use. Not only do they reduce the cost of the composite but Cenospheres often impart performance improvements that might otherwise not have been achieved. It is used in all types of Moulding, Nylon, Low Density Polyethylene and Polypropylene.

6.Automotive: composites, engine parts, sound proofing materials, undercoatings.

Post time: Sep-24-2020