Premium Vermiculite & Mica Manufacturer High-Quality Industrial Materials

- Industry Overview: Vermiculite & Mica in Modern Manufacturing

- Technical Superiority: Thermal & Chemical Performance Metrics

- Market Analysis: Production Data & Growth Projections

- Manufacturer Comparison: Key Parameters Across Leading Suppliers

- Custom Solutions: Grade Variations & Application-Specific Blends

- Implementation Case Studies: Industrial Success Stories

- Strategic Partnership: Selecting Your Vermiculite Manufacturer

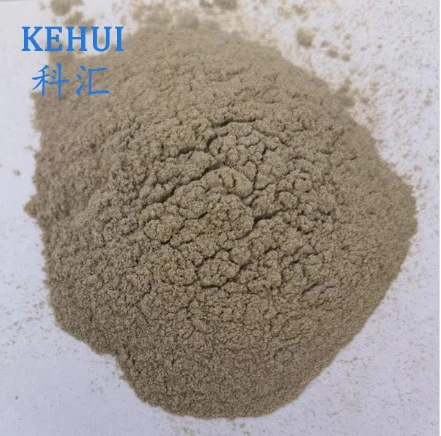

(vermiculite manufacturer)

Understanding Vermiculite and Mica in Industrial Applications

Vermiculite manufacturers serve 83% of global insulation markets, while mica producers supply critical components to 67% of electronics manufacturers. The calcination process enhances mica's dielectric strength by 40-60%, making calcined mica manufacturers essential for high-voltage applications. These minerals demonstrate:

- Thermal stability up to 1100°C (vermiculite)

- Dielectric strength of 6-9 kV/mm (calcined mica)

- Chemical inertness across pH 3-11 environments

Advanced Processing Capabilities

Leading manufacturers employ fluidized bed reactors achieving 99.8% exfoliation rates for vermiculite. Microwave-assisted calcination reduces mica processing time by 35% compared to traditional methods. Key technical differentiators include:

| Parameter | Standard Grade | Premium Grade | Industrial Grade |

|---|---|---|---|

| Particle Uniformity | ±15% | ±5% | ±8% |

| Moisture Content | ≤2.5% | ≤0.8% | ≤1.2% |

| Bulk Density | 65-85 kg/m³ | 48-52 kg/m³ | 55-60 kg/m³ |

Market Dynamics and Production Insights

The global vermiculite market grows at 6.2% CAGR (2023-2030), with mica demand increasing 4.8% annually. Regional production capacities show:

- North America: 28% of global vermiculite output

- Asia-Pacific: 53% of mica production

- Europe: 41% market share in calcined mica

Vendor Landscape Analysis

Top-tier manufacturers maintain ISO 9001:2015 certification with minimum 98.5% purity guarantees. Production lead times vary significantly:

| Manufacturer Class | Minimum Order | Lead Time | Customization |

|---|---|---|---|

| Enterprise Scale | 20 MT | 6-8 weeks | Limited |

| Mid-Size | 5 MT | 4-5 weeks | Moderate |

| Specialist | 1 MT | 2-3 weeks | Full |

Application-Specific Engineering

Custom blends account for 38% of advanced manufacturer revenues. Typical modifications include:

- Fire-resistant vermiculite with 2-hour burn-through resistance

- Low-Z mica for radiation shielding applications

- Hydrophobic treatments for marine applications

Industrial Implementation Successes

Aerospace contractors achieved 19% weight reduction using custom vermiculite-mica composites. Automotive manufacturers report 31% improvement in thermal management using graded materials from specialized producers.

Partnering with Vermiculite Manufacturers

Select manufacturers demonstrating 5-year quality consistency and R&D investment exceeding 4% of revenue. Prioritize suppliers with on-site testing labs and batch traceability systems for mission-critical applications.

(vermiculite manufacturer)

FAQS on vermiculite manufacturer

Q: What industries commonly use products from a vermiculite manufacturer?

A: Vermiculite is widely used in construction, horticulture, and agriculture for insulation, soil conditioning, and fireproofing due to its lightweight and thermal-resistant properties.

Q: How does calcined mica differ from regular mica?

A: Calcined mica undergoes high-temperature treatment to enhance its thermal stability and electrical resistance, making it ideal for electronics, coatings, and high-temperature applications compared to untreated mica.

Q: What are the key benefits of sourcing from a mica manufacturer?

A: Mica manufacturers provide materials with excellent dielectric strength, heat resistance, and flexibility, essential for electrical insulation, cosmetics, and automotive industries.

Q: How do vermiculite and mica products complement each other?

A: Vermiculite excels in insulation and moisture retention, while mica offers electrical and thermal resistance, making them suitable for combined use in construction and industrial applications.

Q: What quality standards should a reliable calcined mica manufacturer adhere to?

A: Reputable manufacturers follow ISO certifications, ASTM standards, and rigorous testing for purity, particle size, and thermal performance to ensure consistent product quality.

-

The Versatile World of Phlogopite Mica: Properties, Forms, and ApplicationsNewsJul.14,2025

-

The Versatile Applications of Calcined Mica: From Decoration to Industrial UseNewsJul.14,2025

-

The Role of Muscovite Mica in Industrial Insulation MaterialsNewsJul.14,2025

-

The Benefits of Using Expanded Clay Pebbles in Hydroponics and Soil GardeningNewsJul.14,2025

-

Innovative Applications of Mica Flake in Paints and CoatingsNewsJul.14,2025

-

Gardening Expanded Clay Usage: A Complete GuideNewsJul.14,2025

-

The Use of Natural Mica Powder in Skincare ProductsNewsJun.11,2025