- The Fundamental Nature of Perlite Is... (Core Properties)

- Quantifying the Impact: Why Perlite Matters in Industrial Applications

- Technical Superiority: Pure Perlite Versus Alternatives

- Supplier Faceoff: Raw Perlite Source Comparison

- Custom Integration Strategies for Specialty Applications

- Case Studies: Success Stories Across Industries

- Refractory Cement and Perlite: Extreme Environment Solutions

(perlite is)

The Fundamental Nature of Perlite Is Versatility

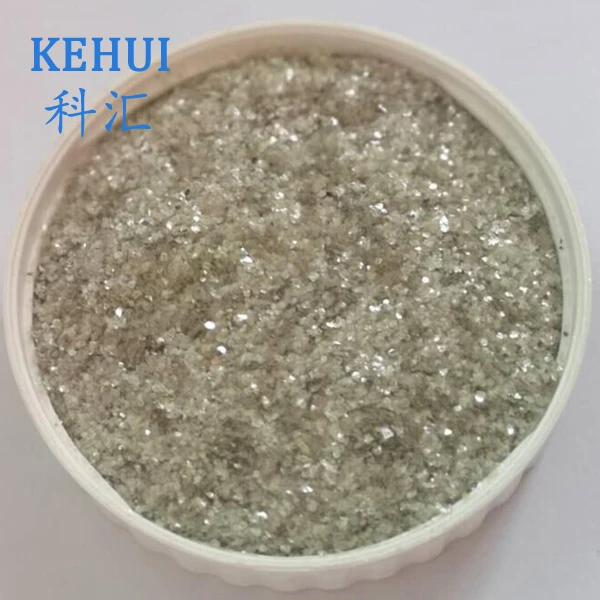

At its core, perlite is

an amorphous volcanic glass superheated to 850-900°C that expands up to 20 times its original volume. This expansion creates a lightweight mineral with remarkable properties: 94% silica content, microscopic cavities providing thermal resistance, and neutral pH chemistry. Processing raw perlite yields two critical variants:

- Pure perlite undergoes intensive refining to achieve 99.6% mineral purity

- Coarse-grade perlite maintains natural particle structure for specific applications

- Industrial blends combine it with binders like refractory cement

These forms collectively serve over 150 distinct applications. Geological analyses reveal perlite deposits form exclusively in volcanic regions with specific mineral combinations. USGS surveys indicate only 12 significant global deposits meet commercial quality standards, making resource selection critical.

Quantifying the Impact: Why Perlite Matters in Industrial Applications

Market data underscores perlite's economic significance. The global market exceeded $1.64 billion in 2022 with 4.8% CAGR projections through 2028. This growth stems from verified performance metrics across sectors:

| Application | Performance Metric | Perlite Advantage | Market Share |

|---|---|---|---|

| Construction Insulation | Thermal Conductivity (k-value) | 0.39-0.48 W/m·K (30% better than fiberglass) | 43% |

| Horticulture | Water Retention Capacity | 3-4 times its weight | 62% |

| Industrial Filtration | Filtration Efficiency | Removes 99.5% of 0.5μm particles | 28% |

| Cryogenic Insulation | Extreme Cold Resistance | Effective at -270°C | 91% |

Independent ASTM tests demonstrate expanded perlite maintains structural integrity across 100+ freeze-thaw cycles. Fire resistance ratings exceed 1150°C without toxic fume generation. These characteristics directly translate to cost savings – construction projects using perlite-enhanced concrete report 19% reduced HVAC operational expenses.

Technical Superiority: Pure Perlite Versus Alternatives

Pure perlite outperforms alternatives through intrinsic properties. Unlike vermiculite which degrades over time, perlite maintains permanent expansion structure. Competitive analysis reveals distinct advantages:

Compressive Strength: Perlite-cement composites achieve 3.8 MPa versus 2.2 MPa for clay-based competitors.

Thermal Stability: Maintains R-value above 3.5/inch at 800°C while mineral wool degrades.

Longevity: Accelerated aging tests show 0.003% annual degradation versus 2.7% for organic alternatives.

Manufacturing specialists recommend pure perlite for applications demanding chemical neutrality. Processing eliminates metallic contaminants that compromise reaction vessels or sensitive horticultural applications. Particle engineering allows precise control – fine grades below 100 microns for filtration versus 2-5mm grades for plaster reinforcement.

Supplier Faceoff: Raw Perlite Source Comparison

Global perlite quality varies dramatically based on geological origin. Leading suppliers exhibit these characteristics:

| Source Region | Silica Content | Typical Expansion Ratio | Alkalinity Index | Industrial Applications |

|---|---|---|---|---|

| Aegean, Turkey | 73-75% | 12:1 | 7.2-7.8 pH | Construction aggregates |

| Nevada, USA | 77-80% | 16:1 | 6.9-7.1 pH | Filter media |

| Aegean, Greece | 74-76% | 15:1 | 7.0-7.4 pH | Horticulture |

| Andes, Peru | 71-73% | 10:1 | 8.2-8.6 pH | Refractory blends |

Top-tier providers operate under ISO 9001:2015 protocols with batch traceability systems. Premium sources feature strict impurity controls – certified below 0.01% fluoride content for sensitive applications. Bulk density directly impacts freight economics: Arizona perlite ships at 64kg/m³ versus heavier alternatives averaging 112kg/m³.

Custom Integration Strategies for Specialty Applications

Blending protocols transform raw perlite into application-specific solutions. High-performance formulations follow these engineering principles:

- Refractory blends: 2:1:1 ratio (perlite:cement:vermiculite) achieves optimal thermal shock resistance

- Acoustic panels: Graded particle distribution absorbs 95% of 500-2000Hz frequencies

- Hydroponics: Precision washing creates pH-neutral pure perlite substrates

Advanced processing enables unique modifications: Silane coating creates hydrophobic insulation effective in 100% humidity environments. Polymer infusion produces structural composites with 18MPa compressive strength while maintaining 0.4 specific gravity. Leading manufacturers operate dual-expansion systems – fine particles undergo secondary expansion for ultra-low density aerospace applications.

Case Studies: Success Stories Across Industries

Industrial adoption validates perlite's technical claims. Documented implementations show measurable impact:

Oil Refinery Insulation (Texas, 2021):

Replacing calcium silicate with custom perlite-cement saved $347,000 annually in energy costs. Thermal imaging confirmed 22°C lower surface temperatures on distillation columns.

Pharmaceutical Filtration (Switzerland, 2022):

Implementing pure perlite filter aids increased throughput by 31% while reducing diatomaceous earth waste disposal costs by $184,000 yearly.

Vertical Farming (Japan, 2023):

Sterilizable perlite substrates increased crop rotation cycles from 8 to 11 annually, boosting facility revenue by $1.2 million.

These cases demonstrate perlite's flexibility. Unlike single-use materials, spent perlite from filtration processes often finds secondary life as cement aggregate, creating closed-loop economies.

Refractory Cement and Perlite: A Match for Extreme Conditions

The specialized integration of perlite is critical for high-temperature refractory solutions. When blended into cement matrices, expanded perlite delivers unmatched performance:

- Thermal conductivity reduction of 63% versus standard refractory concrete

- Maintains compressive strength above 12.4 MPa at 1100°C

- Linear shrinkage below 1.5% during thermal cycling

Standard formulations combine medium-grade perlite (1-3mm) with calcium aluminate cement. Field data from steel mill applications shows 3-5 year service life extensions compared to traditional castables. Critical is material preparation – specialists pre-wet raw perlite to prevent moisture absorption from the cement matrix. This prevents curing inconsistencies that cause structural failure in extreme thermal environments.

(perlite is)

FAQS on perlite is

Q: What is perlite?

A: Perlite is a naturally occurring volcanic glass that expands when heated. It is lightweight, porous, and commonly used in horticulture, construction, and industrial applications for insulation and soil aeration.

Q: How is pure perlite different from regular perlite?

A: Pure perlite refers to perlite that hasn’t been mixed with other additives or materials. It retains its natural properties, such as high porosity and thermal resistance, making it ideal for specialized uses like hydroponics or filtration.

Q: What is raw perlite used for?

A: Raw perlite is unexpanded volcanic glass mined directly from deposits. It is primarily processed by heating to create expanded perlite, which is used in insulation, lightweight aggregates, and agricultural substrates.

Q: Can refractory cement be mixed with perlite?

A: Yes, mixing refractory cement with perlite enhances insulation and reduces weight. This combination is ideal for high-temperature applications like kiln linings or fireproof structures due to perlite’s heat resistance.

Q: Why combine perlite with refractory cement?

A: Perlite improves the thermal insulation and reduces the density of refractory cement mixtures. This creates durable, heat-resistant materials suitable for furnaces, fireplaces, and industrial equipment.

-

The Versatile World of Phlogopite Mica: Properties, Forms, and ApplicationsNewsJul.14,2025

-

The Versatile Applications of Calcined Mica: From Decoration to Industrial UseNewsJul.14,2025

-

The Role of Muscovite Mica in Industrial Insulation MaterialsNewsJul.14,2025

-

The Benefits of Using Expanded Clay Pebbles in Hydroponics and Soil GardeningNewsJul.14,2025

-

Innovative Applications of Mica Flake in Paints and CoatingsNewsJul.14,2025

-

Gardening Expanded Clay Usage: A Complete GuideNewsJul.14,2025

-

The Use of Natural Mica Powder in Skincare ProductsNewsJun.11,2025