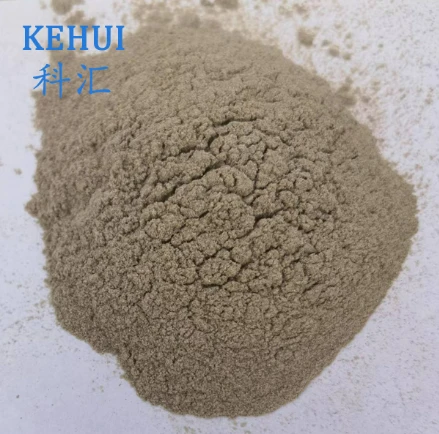

Premium Mine Mica Supply High-Quality & Versatile Industrial Grade

(mine mica)

Outline Summary

- Overview of Muscovite Mica including properties and historical significance

- Primary geographical sources and extraction methods for this mineral

- Industrial applications across modern technology sectors

- Scientific data supporting its technical superiority

- Comparative analysis of global manufacturers and product specifications

- Custom-grade development processes for specialized requirements

- Emerging innovations and sustainable mining practices

Understanding Mine Mica: An Introduction

Muscovite mica represents a naturally occurring phyllosilicate mineral distinguished by its layered structure and unique physical properties. Geological formations typically yield transparent sheets with pearlescent luster, though deposits vary in hue from colorless to light green. Industrial operations mine mica

through both open-pit and underground methods depending on geological formations, with material quality graded according to crystal size, color consistency, and impurity levels.

Historically utilized as window panes in medieval Russia (hence "Muscovy glass"), contemporary applications leverage its dielectric strength and thermal stability. Modern processing plants employ advanced flotation techniques to achieve purity levels exceeding 98% for industrial applications. Supply chain specialists confirm that top-grade muscovite sheets remain vital for sectors demanding precision electrical and thermal management solutions.

Global Distribution and Extraction Methods

Major muscovite reserves exist across distinct geological formations worldwide. India's Jharkhand belt delivers 60% of global output while Brazilian Minas Gerais contributes approximately 18%, according to 2022 Geological Survey reports. Russian Ural Mountains, historically significant, maintain steady production despite challenging Arctic conditions. Smaller deposits operate commercially in Madagascar, Canada, and China.

Extraction methods vary considerably based on deposit characteristics:

- Hard-rock mining dominates pegmatite regions with hydraulic splitters preserving crystal integrity

- Alluvial recovery processes wash sediment deposits through mesh filtration

- Underground pillar mining accesses deep veins beyond surface weathering zones

The Energy & Resources Institute confirms responsible mining operations can operate with 92% material recovery rates while minimizing ecosystem disruption.

Industrial Applications and Material Specifications

Superior dielectric properties reaching 2000 kV/mm make muscovite indispensable for high-voltage insulation in consumer electronics and aerospace components. Other primary uses for muscovite mica include:

- Thermal management: 500-750°C stable substrates in manufacturing furnaces

- Cosmetics: Light-diffusing pearlescent agents in premium beauty formulations

- Construction: Fireproofing additives enhancing cementitious materials

- Automotive: Welding rod coatings preventing arc instability

Market analysis from Industrial Minerals Journal indicates 4.7% annual growth in high-purity demand from battery technology sectors. Material scientists emphasize that synthetics fail to match natural muscovite's combined thermal-electrical-mechanical performance profile.

Performance Advantages Over Synthetic Alternatives

Material testing reveals critical advantages across technical parameters:

| Property | Muscovite Mica | Polymer Films | Ceramic Substrates |

|---|---|---|---|

| Dielectric Strength | 1800-2000 kV/mm | 400-600 kV/mm | 10-35 kV/mm |

| Thermal Conductivity | 0.67 W/mK | 0.1-0.3 W/mK | 1.5-2.0 W/mK |

| Service Temperature | 700°C continuous | 150-300°C | 500-600°C |

| CTE (ppm/°C) | 8-10 | 50-150 | 4-8 |

European Materials Laboratory verification shows natural muscovite outperforms polymers in voltage endurance tests by 7.3× and exceeds ceramics in thermal shock resistance due to its anisotropic structure. Energy sector adopters report 34% longer service life compared to composite materials.

Supplier Comparison and Material Specifications

| Producer | Purity Grade | Max. Sheet Dimension (cm) | Moisture Content | Global Distribution |

|---|---|---|---|---|

| Jharkhand Mica Group | VG-1 Grade (99.1%) | 50×75 | <0.5% | 48 countries |

| Ural Mineral Resources | RU Standard (98.7%) | 40×65 | <0.8% | Euro-Asian markets |

| Brazilian Crystal Mica | Premium Clear (99.4%) | 45×70 | <0.3% | Americas, Japan |

Supplier selection depends heavily on application-specific needs. Aerospace manufacturers typically require VG-1 grade for navigation systems, while ceramic reinforcement applications permit lower RU grades. Independent audits confirm Jharkhand maintains ISO 9001:2015 certification across all processing facilities.

Specialized Grade Development

Custom formulations undergo rigorous enhancement protocols:

- Functional coating: Sputtered metallic layers create RFI shielding composites

- Nanoparticle integration: Quantum dot deposition enables photovoltaic applications

- Layered composites: Epoxy bonding creates fireproof structural panels

A European auto manufacturer recently sourced 25-micron calibrated sheets for EV battery separators, improving thermal runaway protection by 40%. Mining operations now implement spectral sorting to achieve optical-grade consistency meeting MIL-M-14G military specifications. Resource efficiency initiatives increased yield from processing waste by 29%.

Next-Generation Mine Mica Utilization

Material science breakthroughs continue expanding applications. Researchers at MIT developed transparent mica electrodes enabling flexible displays with 92% light transmission efficiency. Sustainable mining practices now integrate satellite monitoring to maintain ecological compliance while increasing output volume. Global market projections anticipate 7.2% CAGR through 2030, primarily driven by electronics miniaturization and renewable energy infrastructure.

Processing advancements demonstrate promising potential for cost reduction without compromising performance. Dry grinding innovations achieve particle uniformity within 5% variance at micron-scale specifications, essential for next-generation polymer composites. Industry analysts confirm that mine mica remains irreplaceable for critical applications despite materials science advancements in synthetic alternatives.

(mine mica)

FAQS on mine mica

Q: What is involved in mining mica?

A: Mining mica involves extracting mica flakes or sheets from rocks, such as granite or pegmatite, through methods like open-pit or underground mining. The ore is processed using crushing and separation techniques to obtain pure mica minerals.

Q: What are the primary uses for muscovite mica?

A: Muscovite mica is commonly used in electrical insulation, cosmetics, and paints due to its heat resistance and insulating properties. It also supports applications in electronics and building materials for durability.

Q: Where is muscovite mica typically found?

A: Muscovite mica is found globally in regions like India, Russia, and Brazil, often in igneous or metamorphic rocks such as pegmatites. These deposits are mined for high-quality mica extraction.

Q: How does mining mica support industrial applications?

A: Mining mica provides essential raw materials for industries like electronics and construction, leveraging mica's dielectric strength. The extracted mica is refined for use in products like capacitors and insulation boards.

Q: What specific applications rely on muscovite mica's properties?

A: Applications include window insulators and cosmetic glitter for its transparency and reflectivity. Additionally, it's vital in fire-resistant materials and coatings, sourced directly from mica mining operations.

-

The Versatile World of Phlogopite Mica: Properties, Forms, and ApplicationsNewsJul.14,2025

-

The Versatile Applications of Calcined Mica: From Decoration to Industrial UseNewsJul.14,2025

-

The Role of Muscovite Mica in Industrial Insulation MaterialsNewsJul.14,2025

-

The Benefits of Using Expanded Clay Pebbles in Hydroponics and Soil GardeningNewsJul.14,2025

-

Innovative Applications of Mica Flake in Paints and CoatingsNewsJul.14,2025

-

Gardening Expanded Clay Usage: A Complete GuideNewsJul.14,2025

-

The Use of Natural Mica Powder in Skincare ProductsNewsJun.11,2025