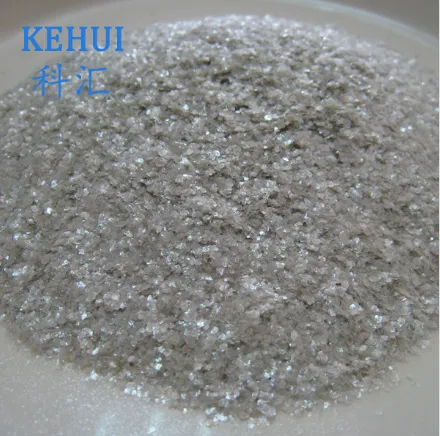

Mica flakes have emerged as a versatile and sought-after material across a wide range of industries. Known for their glittering appearance and impressive durability, mica flakes are produced by crushing natural mica into small, flat pieces. These flakes are highly valued for their reflective properties, resistance to heat, and ability to enhance both visual and functional aspects of finished products. From flooring and countertops to paints and coatings, mica flakes are making their mark as a reliable and attractive material in modern design and manufacturing.

Mica Flakes for Sale: Meeting the Growing Demand for Quality Materials

As industries increasingly seek out unique and durable decorative materials, the availability of mica flakes for sale has expanded globally. Suppliers now offer mica flakes for sale in a variety of sizes, colors, and purities to suit different applications, from decorative concrete to specialty coatings. Businesses looking for mica flakes for sale can benefit from competitive pricing, customized orders, and consistent quality when sourcing directly from reputable manufacturers.

Choosing the right supplier for mica flakes for sale ensures access to products that meet specific industry standards, including high-temperature resistance, non-toxicity, and UV stability. Whether used in commercial flooring systems or high-end architectural designs, mica flakes for sale offer an exceptional combination of beauty and performance that continues to attract designers, builders, and manufacturers worldwide.

Mica Flake in Concrete: Enhancing Aesthetics and Durability

The use of mica flakes for concrete has become increasingly popular as designers and architects seek to create more dynamic and visually striking surfaces. When integrated into concrete mixes, mica flakes for concrete provide a natural sparkle and depth that elevate the overall appearance of floors, countertops, and decorative panels. The reflective nature of mica flakes for concrete not only enhances visual appeal but also contributes to better light diffusion within indoor spaces, creating a brighter and more inviting atmosphere.

Beyond aesthetics, mica flakes for concrete also offer functional benefits. Their stable structure adds slight reinforcement to the surface layer, improving wear resistance and durability. Because mica flakes for concrete are non-reactive and highly stable, they maintain their integrity over time, even when exposed to moisture, chemicals, or UV radiation. This makes them an ideal additive for both residential and commercial construction projects aiming for long-term performance combined with stunning visual impact.

How to Use Mica Flakes: Practical Applications Across Industries

Understanding how to use mica flakes effectively is key to maximizing their benefits across different projects. In decorative concrete, mica flakes are typically broadcast onto the surface of wet concrete or epoxy coatings, followed by sealing to lock them in place. This method ensures an even distribution and protects the flakes from abrasion and environmental damage. When adding mica flakes to paints or coatings, they can be mixed directly into the formulation or applied as a top layer to achieve the desired texture and sheen.

In arts and crafts, mica flakes are often sprinkled onto adhesives, incorporated into resin projects, or blended into paper and textiles to add shimmer and texture. Industrial applications leverage mica flakes for their thermal resistance and insulating properties, incorporating them into specialty paints, plasters, and even roofing materials. Regardless of the method, knowing how to use mica flakes properly ensures they deliver maximum aesthetic and functional value to any project.

میکا فلیک FAQs

Where can I find high-quality mica flakes for sale?

High-quality mica flakes for sale can be sourced from specialized mineral suppliers, industrial raw material distributors, and online marketplaces that cater to construction and decorative industries. When purchasing, it’s important to check the supplier’s reputation, product specifications, and whether the mica flakes for sale meet industry standards for purity, color consistency, and size grading.

What are the benefits of adding mica flakes to concrete?

Incorporating mica flakes for concrete provides both aesthetic and functional advantages. Visually, the flakes create a shimmering, dynamic surface that enhances the overall design. Functionally, mica flakes for concrete improve surface durability, add slight reinforcement, and increase UV resistance. These properties make them ideal for high-traffic areas, decorative installations, and projects requiring long-lasting beauty.

Can I use mica flakes in epoxy flooring systems?

Yes, mica flakes are an excellent addition to epoxy flooring systems. They are typically broadcast into the wet epoxy to create a textured, decorative surface. The reflective quality of mica flakes enhances the visual appeal of the floor while the physical properties contribute to improved traction, abrasion resistance, and longevity. Knowing how to use mica flakes properly in epoxy applications ensures an attractive and durable finish.

How are mica flakes different from other decorative aggregates?

Unlike traditional aggregates like quartz or colored chips, mica flakes offer a unique combination of natural sparkle, lightweight structure, and high heat resistance. Mica flakes can create a more subtle and elegant shimmer, adding depth without overwhelming the overall design. Their non-toxic and stable nature also makes them a safer, more environmentally friendly option compared to some synthetic alternatives.

What is the best way to apply mica flakes for artistic projects?

For arts and crafts, mica flakes can be applied by sprinkling them onto wet adhesives, mixing them into resins, or embedding them in coatings or sealants. When learning how to use mica flakes in artistic projects, it’s important to ensure even distribution and to seal the flakes properly to prevent shedding. Their lightweight nature and brilliant reflectivity make them ideal for adding dimension and texture to a wide range of creative works.

-

The Versatile World of Phlogopite Mica: Properties, Forms, and ApplicationsاخبارJul.14,2025

-

The Versatile Applications of Calcined Mica: From Decoration to Industrial UseاخبارJul.14,2025

-

The Role of Muscovite Mica in Industrial Insulation MaterialsاخبارJul.14,2025

-

The Benefits of Using Expanded Clay Pebbles in Hydroponics and Soil GardeningاخبارJul.14,2025

-

Innovative Applications of Mica Flake in Paints and CoatingsاخبارJul.14,2025

-

Gardening Expanded Clay Usage: A Complete GuideاخبارJul.14,2025

-

The Use of Natural Mica Powder in Skincare ProductsاخبارJun.11,2025