Phlogopite Mica: An important rock forming mineral and its applications

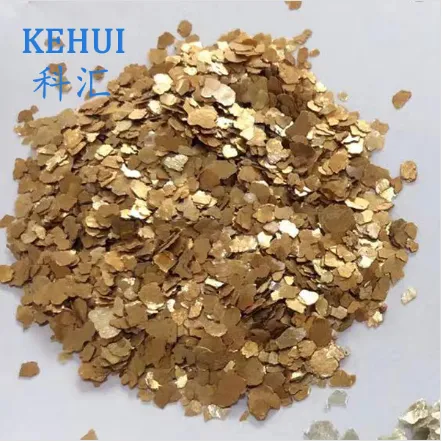

Mica flogopita, As a member of the mica family, it is an important magnesium aluminum silicate mineral. Its typical yellow brown to reddish brown appearance makes it unique among many minerals. This article will explore the crystal structure, genesis, properties, and applications of Phlogopite Mica in different fields, demonstrating its important position in geology and industrial applications.

Phlogopite Mica belongs to the monoclinic crystal system and has a typical sheet-like structure

Its crystal structure consists of alternating stacking of tetrahedral and octahedral layers, connected by potassium ions. This unique layered structure endows Mica flogopita with excellent cleavage properties, allowing it to be easily peeled off into thin sheets. In addition, Phlogopite Mica also contains small amounts of elements such as iron and fluorine, and changes in the content of these elements can affect its color and properties.

The genesis of Phlogopite Mica is related to various geological processes

Phlogopite mica flakes are commonly found in magnesian ultrabasic rocks such as kimberlite and peridotite, and are products of magnesium iron mineral alteration during magmatic processes. Meanwhile, Phlogopite Mica may also have formed during regional metamorphism, especially in rocks rich in magnesium that have undergone high-temperature and high-pressure processes. In addition, hydrothermal alteration is also an important pathway for the formation of Phlogopite Mica. Hydrothermal fluids rich in potassium and magnesium react with surrounding rocks, promoting the crystallization and precipitation of Mica flogopita.

Phlogopite Mica has various physical and chemical properties, making it widely applicable in the industrial field

Phlogopite mica flakes have excellent electrical insulation, good high temperature resistance, high chemical stability, and are not easily corroded by acid and alkali. These characteristics make Phlogopite Mica widely used as an insulating material in the electronics industry, such as in the manufacture of electronic components such as capacitors and resistors. In addition, the sheet-like structure of Phlogopite Mica gives it good flame retardancy, making it often used as an additive in fire-resistant coatings and building materials. In the metallurgical industry, Phlogopite Mica can serve as a protective agent during the steelmaking process to prevent oxidation of molten steel. Phlogopite Mica powder can also be used to manufacture cosmetics, lubricants, and other products.

In summary, Phlogopite Mica is a mineral of significant geological and industrial importance. Its unique crystal structure, diverse origins, and excellent physical and chemical properties make it play an important role in geological research and industrial applications. With the continuous development of science and technology, our understanding of Phlogopite Mica will deepen and its application fields will become more extensive.

Phlogopite Mica FAQas

What is Phlogopite Mica?

Phlogopite Mica is a natural magnesium aluminum silicate mineral with the chemical formula KMg ∝ (AlSi ∝ O ₁₀) (F, OH) ₂, belonging to layered silicate minerals. Compared with muscovite, it contains more magnesium and iron, and its color is usually amber, brown, or reddish brown. It has excellent high temperature resistance and insulation properties.

What are the main features of Phlogopite Mica?

High temperature resistance: can withstand high temperatures of 800 to 1000 ° C, better than muscovite (500 to 600 ° C).

Insulation: High resistivity, suitable for high-voltage electrical equipment.

Chemical stability: resistant to acid, alkali, and organic solvent corrosion.

Mechanical properties: flexible, peelable into ultra-thin sheets, strong impact resistance.

Color and Transparency: Typically semi transparent to opaque amber or dark brown in color.

What are the main application areas of Phlogopite Mica?

High temperature industry: metallurgical furnace lining, refractory materials, welding protective equipment.

Electronic appliances: high-voltage insulation materials, insulation layers for electric heating equipment.

Building materials: fireproof board, flame-retardant coating, decorative materials.

Plastic/rubber: enhances heat resistance and mechanical strength.

Cosmetics: Dark pearl pigments (requiring high-purity processing).

What is the difference between Phlogopite Mica and Muscovite Mica?

Ingredients: Phlogopite Mica contains magnesium (Mg) and a small amount of iron (Fe), while muscovite contains aluminum (Al).

Temperature resistance: Phlogopite Mica has higher temperature resistance (1000 ° C vs. 600 ° C).

Color: Phlogopite Mica appears amber/brown, while muscovite is colorless or light colored.

Electrical performance: White mica has slightly better insulation, but Phlogopite Mica is more resistant to high temperature aging.

How to evaluate the quality of Phlogopite Mica?

Key indicators include:

Temperature resistance level: It is necessary to specify the long-term use temperature (such as 800 ° C or 1000 ° C).

Purity: Impurities such as Fe ₂ O ∝ affect performance (electronic grade requires<1%).

Particle size and thickness: Industrial fillers commonly use 20200 μ m, and ultra-thin sheets are used for high-end insulation.

Moisture content: Calcination treatment can reduce moisture absorption (especially in high-temperature applications).

-

The Versatile World of Phlogopite Mica: Properties, Forms, and ApplicationsNoticiasJul.14,2025

-

The Versatile Applications of Calcined Mica: From Decoration to Industrial UseNoticiasJul.14,2025

-

The Role of Muscovite Mica in Industrial Insulation MaterialsNoticiasJul.14,2025

-

The Benefits of Using Expanded Clay Pebbles in Hydroponics and Soil GardeningNoticiasJul.14,2025

-

Innovative Applications of Mica Flake in Paints and CoatingsNoticiasJul.14,2025

-

Gardening Expanded Clay Usage: A Complete GuideNoticiasJul.14,2025

-

The Use of Natural Mica Powder in Skincare ProductsNoticiasJun.11,2025