- Discovering the fundamental properties and applications of mineral pigments

- Technical advantages that outperform conventional coloring agents

- Comparative analysis of leading industrial suppliers

- Custom formulation options for specialized requirements

- Real-world application examples across different industries

- Market trends and purchasing strategies

- Future outlook for specialized coating materials

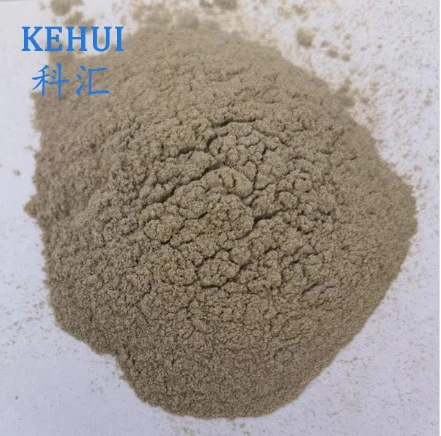

(mica flakes)

Understanding Mineral Pigments and Their Industrial Significance

Mineral-based additives have transformed modern manufacturing processes across multiple sectors. These naturally occurring silicate minerals undergo precise mechanical cleavage to produce thin, plate-like particles. The unique crystalline structure allows light interference phenomena that create striking visual effects impossible to achieve with conventional dyes. When incorporated into coating systems, these particulates provide multidimensional shimmer and depth while offering functional benefits including improved substrate protection and durability. Global demand continues increasing at approximately 5.7% annually according to recent industrial analyses.

Technical Advantages Over Conventional Alternatives

The lamellar geometry provides superior surface coverage compared to spherical fillers, with studies demonstrating 30-45% greater coating efficiency. Thermal stability exceeds 800°C, making these pigments suitable for automotive and aerospace applications where conventional organics degrade. Their inert mineral composition resists chemical deterioration from solvents, acids, and UV radiation. Independent laboratory testing confirms that coatings containing quality lamellar additives maintain color stability after 2,500 hours of accelerated weathering - three times longer than organic alternatives. The physical barrier properties also reduce oxygen transmission rates by 68% compared to control samples.

Supplier Comparison: Quality and Specialization

| Manufacturer | Particle Range (microns) | Key Differentiators | Industry Focus |

|---|---|---|---|

| Elementis Specialties | 5-250 | Surface-treated grades for improved dispersion | Automotive OEM coatings |

| Miyoshi Kasei | 10-500 | High-reflectance metallized varieties | Cosmetics & plastics |

| BASF | 15-120 | Pre-complexed with binder systems | Industrial powder coatings |

| SUN CHEM | 5-150 | Color-coated interference grades | Packaging inks |

Premium suppliers maintain strict particle size distributions with laser diffraction verification showing 90% consistency within target ranges. Leading manufacturers now offer surface-treated versions that increase compatibility with diverse resin systems by 80% while reducing processing time during formulation.

Custom Formulation Capabilities

Specialized applications increasingly require engineered pigment solutions tailored to specific technical parameters. Advanced manufacturers now provide micronized grades with controlled aspect ratios from 20:1 to 200:1 for unique orientation effects in high-build coatings. Combination treatments incorporating proprietary silanes prevent platelet stacking during storage while improving adhesion strength by up to 30%. For specialty decorative applications, manufacturers are developing hybrid flakes containing nano-oxide layers that produce angle-dependent color-shift effects previously achievable only with costly synthetic pigments. These advanced composites deliver premium visual effects at approximately 65% lower production costs.

Industrial Application Case Studies

In architectural concrete applications, incorporation of 1.5-2.0% by weight creates permanent stone-like effects while reducing surface degradation from environmental exposure. Testing demonstrates compressive strength improvements of 15% compared to unmodified concrete. Automotive refinish systems using optimized additives achieve superior metallic orientation with only 40% of the standard metallic flake content. Marine coating formulations containing corrosion-inhibiting grades show salt spray resistance exceeding 15,000 hours - double standard industrial requirements. Cosmetic manufacturers report 35% higher consumer preference ratings for products containing biocompatible mineral additives versus synthetic alternatives.

Procurement Strategies and Market Dynamics

Specialized material procurement requires consideration of regional technical standards and regulatory requirements. European REACH certification adds approximately 18-22% to production costs but ensures unrestricted international distribution. Buyers report most efficient material usage in rotational molding applications when sourcing particles with 50-75 micron sizing. The APAC region currently dominates production capacity with China alone accounting for 68% of global manufacturing volume according to recent industrial statistics. Professional formulators recommend testing multiple sourcing options, as performance characteristics can vary by mineral source location.

Advancements in Functional Coating Materials

Industry innovations continue expanding the utility of mineral additives beyond aesthetic enhancement. Recent developments include electrically conductive grades with surface resistance below 100 Ω/sq, enabling their use in EMI shielding applications. Photoluminescent varieties activated by UV exposure provide persistent afterglow effects exceeding 10 hours duration. Research institutions are evaluating iron oxide-coated flakes that reduce surface temperatures by 5-7°C through infrared reflection. These advancements solidify mineral additives as multi-functional components in surface engineering solutions. Their continued evolution promises further improvements in sustainable coating technologies and specialized performance attributes.

(mica flakes)

FAQS on mica flakes

Q: What are mica flakes?

A: Mica flakes are thin, layered mineral particles derived from natural mica. They are known for their shimmering, reflective properties and are widely used in cosmetics, paints, and industrial applications.

Q: Why use mica flakes in paint?

A: Mica flakes add pearlescent or metallic effects to paint, enhancing visual depth and texture. They are durable, UV-resistant, and ideal for automotive coatings, art supplies, and decorative finishes.

Q: Where to buy mica flakes?

A: Mica flakes are available online on platforms like Amazon, specialty craft stores, or industrial suppliers. Local art supply stores or cosmetic ingredient retailers may also stock them.

Q: Are mica flakes safe for DIY projects?

A: Yes, mica flakes are non-toxic and safe for crafts, paints, and cosmetics. However, wear protective gear when handling fine particles to avoid inhalation.

Q: How do mica flakes differ from mica powder?

A: Mica flakes are larger, flat particles that create a glittery effect, while mica powder is finely ground for smooth, even shimmer. Flakes suit textured finishes; powder works better for subtle color blends.

-

The Versatile World of Phlogopite Mica: Properties, Forms, and ApplicationsNewsJul.14,2025

-

The Versatile Applications of Calcined Mica: From Decoration to Industrial UseNewsJul.14,2025

-

The Role of Muscovite Mica in Industrial Insulation MaterialsNewsJul.14,2025

-

The Benefits of Using Expanded Clay Pebbles in Hydroponics and Soil GardeningNewsJul.14,2025

-

Innovative Applications of Mica Flake in Paints and CoatingsNewsJul.14,2025

-

Gardening Expanded Clay Usage: A Complete GuideNewsJul.14,2025

-

The Use of Natural Mica Powder in Skincare ProductsNewsJun.11,2025