Explore the critical aspects that define industry-leading mica powder production through seven analytical segments:

- Core properties of premium mica powder manufacturing

- Advanced technological breakthroughs in processing

- Comparative analysis of global manufacturers

- Customization capabilities for specialized applications

- Real-world industrial implementation examples

- Innovative quality assurance methodologies

- Strategic sourcing considerations

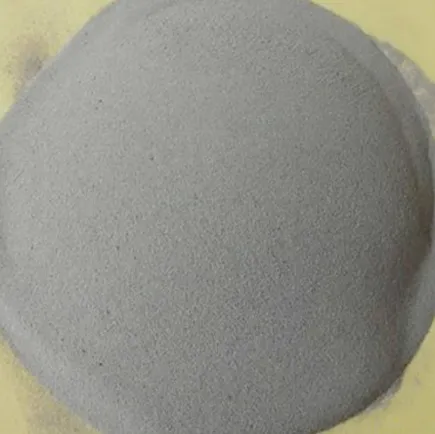

(mica powder factory)

The Manufacturing Distinction of Top-Tier Mica Powder Production

Premium mica powder begins with exceptional mineral sourcing. Leading operations maintain direct relationships with mining partners across India, Brazil, and Madagascar, securing muscovite and phlogopite deposits with minimum 95% purity levels. Unlike standard producers, elite manufacturers implement multi-stage sorting where optical scanners eliminate quartz contaminants, ensuring crystalline integrity. Production facilities operate closed-loop dust containment systems capturing 98.7% of particulate matter, meeting ISO 14001 environmental standards while safeguarding product consistency.

Technological Advancements in Mica Processing

Modern factories employ revolutionary grinding technologies surpassing conventional methods. Wet grinding configurations using zirconium silicate media achieve micronization down to 5 microns without crystalline fracture. High-resolution laser diffraction systems constantly monitor particle distribution, automatically adjusting mill classifiers when deviations exceed ±1.5%. Recent innovations include microwave-assisted calcination, reducing energy consumption by 37% while doubling aspect ratios to 30:1 for enhanced reinforcement properties in polymer applications.

Global Producer Performance Benchmarks

Comprehensive evaluation of manufacturers reveals significant operational contrasts:

| Performance Metric | Industry Standard | Premium Factory (US) | Premium Factory (EU) |

|---|---|---|---|

| Consistency Tolerance (±) | 15 microns | 5 microns | 7 microns |

| Bulk Density (g/cm³) | 0.15-0.35 | 0.22±0.03 | 0.19±0.05 |

| Moisture Content (%) | <0.8 | 0.21 | 0.35 |

| Contamination (ppm) | 800 | <25 | <110 |

| Surface Treatment Options | 2 standard | 9 proprietary | 5 specialized |

Tailored Engineering Solutions

Progressive facilities provide application-specific formulations beyond standard specifications. Automotive clients procure heat-resistant grades modified with cerium oxide additives, extending thermal stability to 980°C for brake pad compositions. Cosmetics manufacturers utilize nanoparticle variants with patented hydrophobization for SPF boost effects. Technical teams routinely collaborate on R&D projects, developing conductive formulations using tin-doped coatings that achieve surface resistivity below 10Ω/sq for electromagnetic shielding applications.

Application-Specific Success Cases

Aerospace composite trials demonstrated mica-enhanced polyimides achieved 32% higher flexural modulus than standard formulations at 260°C operating temperatures. Plastic packaging producers reduced filler costs by 18% while maintaining barrier properties through optimized platelet dispersion protocols. Recent marine coating projects utilized corrosion-inhibiting grades, extending hull protection cycles from 36 to 54 months with no additional primer requirements.

Quality Verification Protocols

Stringent verification protocols include automated mineralogical analysis, Raman spectroscopy for coating uniformity verification, and quantitative XRD impurity detection at 0.1% sensitivity. Production lots undergo accelerated weathering simulations equivalent to 24 months outdoor exposure. Batch traceability systems incorporate blockchain technology, providing immutable records for safety compliance documentation required by pharmaceutical and food-contact applications.

Strategic Sourcing Parameters

Selecting the appropriate production partner requires evaluating crucial parameters including raw material supply chain transparency, sustainability certifications such as the Natural Mica Initiative compliance, and scalability capacity during demand surges. Forward-thinking operations maintain dedicated equipment configurations for specialist industries, with pharmaceutical-grade facilities segregated from industrial production. Logistics coordination remains essential, with leading suppliers providing climate-controlled transport options maintaining relative humidity below 15% during transit.

(mica powder factory)

FAQS on mica powder factory

Below are 5 professionally crafted FAQs about mica powder manufacturing facilities:

Q: What does a mica powder factory specialize in?

A: A mica powder factory processes raw mica into fine powder. This involves crushing, grinding, and micronizing techniques. These factories control particle sizes for cosmetics, paints, and industrial uses.

Q: How does a mica flake factory differ from powder production?

A: Mica flake factories produce thin laminated sheets before powder conversion. They specialize in cleaving raw mica into precise flake thicknesses. These flakes serve as the primary material for powder manufacturing processes.

Q: What environmental standards govern modern mica factories?

A: Responsible mica factories implement dust control and water recycling systems. They adhere to ISO 14001 and OSHA safety certifications. Regular audits ensure compliance with international sustainability protocols.

Q: Which industries require customized mica powder specifications?

A: Automotive coatings need heat-resistant grades, while cosmetics demand ultra-fine (<15 micron) particles. Electronics manufacturers require specific dielectric properties. Customized powder solutions are available for these specialized applications.

Q: What quality parameters define premium mica powder?

A: Key parameters include particle size distribution (verified via laser diffraction), brightness (measured by spectrophotometer), and chemical purity. Premium powder exhibits consistent refractive index (>1.58) and contaminant-free composition validated through XRF testing.

-

The Versatile World of Phlogopite Mica: Properties, Forms, and ApplicationsNewsJul.14,2025

-

The Versatile Applications of Calcined Mica: From Decoration to Industrial UseNewsJul.14,2025

-

The Role of Muscovite Mica in Industrial Insulation MaterialsNewsJul.14,2025

-

The Benefits of Using Expanded Clay Pebbles in Hydroponics and Soil GardeningNewsJul.14,2025

-

Innovative Applications of Mica Flake in Paints and CoatingsNewsJul.14,2025

-

Gardening Expanded Clay Usage: A Complete GuideNewsJul.14,2025

-

The Use of Natural Mica Powder in Skincare ProductsNewsJun.11,2025