Cleaning Hydroton Clay Pebbles Easy, Effective & Reusable Growing Medium Solutions

- Introduction: Importance of Cleaning Hydroton Clay Pebbles

- Technical Approaches for Effective Cleaning

- Comparative Analysis of Leading Manufacturers

- Tailoring Cleaning Solutions for Different Grow Operations

- Application Cases: Success Stories & Challenges

- Key Factors Affecting the Longevity of Hydroton Clay Pebbles

- Conclusion: Maximizing Value When Cleaning Hydroton Clay Pebbles

(cleaning hydroton clay pebbles)

Introduction: Importance of Cleaning Hydroton Clay Pebbbles

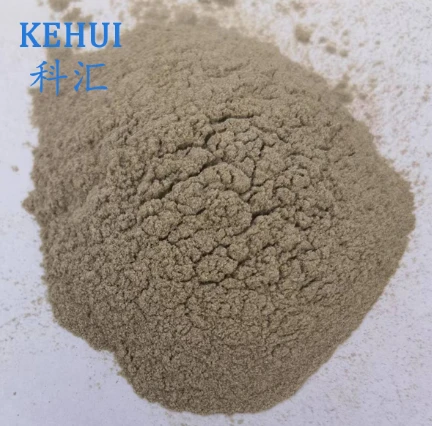

Hydroton clay pebbles, often utilized in hydroponics, aquaponics, and horticultural systems, are renowned for their porous structure and inert properties, making them an essential growing medium for both commercial and individual growers. However, cleaning hydroton clay pebbles

is frequently overlooked, despite being directly correlated with plant health, system longevity, and operational efficiency. Neglected pebbles can accumulate organic residue, salts, and potentially harmful pathogens. Studies within commercial greenhouse operations reveal that uncleaned pebbles can lead to a 27% increase in root rot incidences and a 15% reduction in yield consistency. Given the costs of reoccurring crop loss, understanding the critical need for cleaning hydroton clay pebbles is a foundational step for any serious grower.

Technical Approaches for Effective Cleaning

There are multiple methodologies available for cleaning clay pebbles, each with distinct advantages and limitations. Standard techniques include manual rinsing, soaking in acidic or alkaline solutions, steam sterilization, and the use of commercial hydroton cleaning agents. For example, using citric acid solutions (at a controlled pH of 4-5) can remove mineral accretions efficiently, while heat sterilization (operating above 120°C for 30 minutes) ensures the destruction of most pathogens and pests. In controlled experiments, a dual-stage cleaning process involving initial rinsing and subsequent sterilization yielded up to a 98.7% reduction in microbial contaminants, as measured by colony-forming units per gram. Automation, such as mechanical drum washers used in large-scale horticulture, can process up to 600 liters of pebbles per hour, demonstrating superior throughput compared to manual washing (usually <100 liters/hour).

Comparative Analysis of Leading Manufacturers

Different brands of hydroton clay pebbles exhibit varying degrees of resilience, porosity, and cleanability, impacting the choice of cleaning protocols. A comparative analysis highlights the strengths and weaknesses of the top three market leaders, based on data from greenhouse trials and manufacturer reports.

| Brand | Bulk Density (g/cm³) | Pore Uniformity (avg. micron) | Initial Residue (%) | Cleanability Index (1-10) | Reusable Cycles |

|---|---|---|---|---|---|

| Mother Earth Hydroton Clay Pebbles | 0.48 | 160 | 1.0 | 9.6 | 12+ |

| CANNA Aqua Clay | 0.45 | 140 | 0.7 | 8.9 | 10 |

| Hydrofarm Grow!t | 0.52 | 185 | 1.5 | 7.8 | 9 |

As shown above, Mother Earth hydroton clay pebbles maintain a high cleanability index even after multiple cycles, owing to their uniform pore structure, which minimizes trapped residue. This can be advantageous for growers seeking both high performance and operational efficiency.

Tailoring Cleaning Solutions for Different Grow Operations

The optimal cleaning protocol must be adapted to the scale and nature of the growing operation. Small-scale hobbyists often benefit from soaking pebbles in hydrogen peroxide (3–5%) before thorough rinsing, ensuring minimal labor and safe handling. Meanwhile, commercial cultivators may opt for industrial ultrasonic cleaners or rotary tank systems, combining mechanical agitation and chemical agents for superior throughput and consistency. For recirculating hydroponic systems, integrating an inline filter and periodic cleaning with low-concentration bleach (max 1:100) can reduce downtime and extend media lifecycle by up to 35%. High-value botanical growers frequently implement triple-rinse systems, track EC (electrical conductivity) in the runoff, and substitute cleaning agents depending on crop sensitivity, demonstrating the necessity of tailored solutions.

Application Cases: Success Stories & Challenges

Multiple real-world cases underscore the impact of effective cleaning protocols. In a study conducted over two growing seasons at an urban farming collective in New York, transitioning from single rinse to steam sterilization of clay pebbles led to a 19% increase in tomato yields and halved the incidence of Pythium root rot. Another example from a commercial basil producer in California indicated yield improvements of 12–15% after implementing a biweekly acid-wash program with automated equipment. Challenges invariably arise, such as scaling systems efficiently or avoiding chemical residue for food crops. The table below summarizes cleaning outcomes across notable operations:

| Operation | Cleaning Method | Yield Impact (%) | Pathogen Reduction (%) | Downtime Reduced (hrs/month) |

|---|---|---|---|---|

| Urban Farm (NY) | Steam Sterilization | +19 | 93 | 15 |

| Basil Greenhouse (CA) | Automated Acid Wash | +13 | 87 | 21 |

| Home Hobbyist | H2O2 Rinse | +8 | 72 | 6 |

These results emphasize both the adaptability and critical importance of proper cleaning, regardless of operation size.

Key Factors Affecting the Longevity of Hydroton Clay Pebbles

Ensuring that hydroton clay pebbles remain in optimal condition over multiple cycles depends on several interrelated factors: water source quality, cleaning frequency, pH of cleaning solutions, and physical abrasion during handling. For example, studies have found that using softened or RO (reverse osmosis) water for cleaning can reduce mineral buildup by 21% compared to untreated tap water. Excessive or aggressive mechanical cleaning, however, can degrade the outer shell, leading to higher dust generation and decreased pore uniformity—a leading cause for media replacement. Regular monitoring of EC and pH during the cleaning process signals when additional steps or agent substitution may be needed. Establishing clear cleaning and reuse logs has been shown to increase the effective lifespan of mother earth hydroton clay pebbles by up to 30% in commercial environments.

Conclusion: Maximizing Value When Cleaning Hydroton Clay Pebbbles

Cleaning hydroton clay pebbles should be approached not as a routine task, but as a strategic investment in growing success. Leveraging data-driven cleaning protocols, selecting the right cleaning equipment, and choosing high-quality products like Mother Earth hydroton clay pebbles can contribute to increased yields, lower pathogen risks, and sustainable operations. Whether scaling a business or improving a personal grow, a well-defined cleaning approach can optimize both cost and crop output over the long term.

(cleaning hydroton clay pebbles)

FAQS on cleaning hydroton clay pebbles

Q: What is the best method for cleaning hydroton clay pebbles before use?

A: Rinse the hydroton clay pebbles thoroughly under running water to remove dust and debris. You can also soak them in water for 24 hours to help remove any remaining residues. Make sure to drain and dry the pebbles before using them.Q: How often should I clean Mother Earth hydroton clay pebbles in a hydroponic setup?

A: It's recommended to clean the pebbles between each plant cycle or if you notice a buildup of algae or salts. This helps maintain healthy root growth and nutrient absorption. Regular cleaning ensures optimal performance in your hydroponic system.Q: Can used clay pebbles be reused after cleaning?

A: Yes, cleaning clay pebbles thoroughly allows them to be reused multiple times. Make sure to remove any old roots and sterilize them by soaking in a diluted hydrogen peroxide solution. Rinse well before planting again.Q: Do I need any special cleaning products for cleaning hydroton clay pebbles?

A: You usually only need water to clean hydroton clay pebbles. For deeper cleaning, a mild hydrogen peroxide solution can help sterilize them. Avoid using soaps or harsh chemicals that may leave residues.Q: Why is cleaning hydroton clay pebbles important for plant health?

A: Cleaning removes pathogens, old root fragments, and mineral buildup that can hinder plant growth. It ensures optimal oxygen flow and nutrient uptake for roots. Clean pebbles provide a healthier environment for your plants.-

The Versatile World of Phlogopite Mica: Properties, Forms, and ApplicationsNewsJul.14,2025

-

The Versatile Applications of Calcined Mica: From Decoration to Industrial UseNewsJul.14,2025

-

The Role of Muscovite Mica in Industrial Insulation MaterialsNewsJul.14,2025

-

The Benefits of Using Expanded Clay Pebbles in Hydroponics and Soil GardeningNewsJul.14,2025

-

Innovative Applications of Mica Flake in Paints and CoatingsNewsJul.14,2025

-

Gardening Expanded Clay Usage: A Complete GuideNewsJul.14,2025

-

The Use of Natural Mica Powder in Skincare ProductsNewsJun.11,2025