- Overview of mica's industrial significance and key properties

- Technical advantages determining mica performance metrics

- Comparative analysis of global mica suppliers

- Customized solutions for specific application requirements

- Case examples across major industries

- Ethical sourcing and sustainability framework

- Critical selection factors for mica procurement

(mica suppliers)

Introduction to Industrial Mica Applications

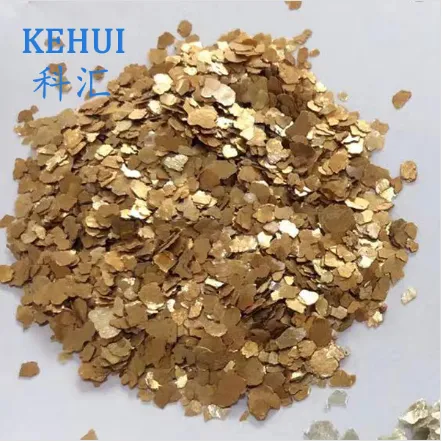

The mineral mica constitutes a $5.2 billion global market with diverse applications across insulation, construction, and electronics. Muscovite mica represents 38% of industrial consumption due to its superior dielectric strength (up to 2000 MV/m), while phlogopite and vermiculite varieties serve specialized high-heat environments. Leading mica suppliers provide material solutions meeting ISO 9001:2015 standards with thermal stability from -270°C to +1000°C. The unique layered silicate structure enables applications in critical sectors where alternatives fail, driving 6.1% annual market growth through 2029.

Technical Advantages of Premium-Grade Mica

Performance advantages begin with crystal lattice integrity. Top-grade muscovite maintains dielectric constant between 5.4-8.7 even at GHz frequencies, outperforming synthetic polymers by 23-48% in high-frequency circuits. Vermiculite expanded through exfoliation achieves 0.065 W/m·K thermal conductivity - critical for fireproofing applications. Material specifications determine application viability:

- Dielectric breakdown resistance: 115-200 kV/mm

- Water absorption rates: <0.3% by volume

- Tensile strength: 170-350 MPa parallel to cleavage

- Acid/alkali resistance: pH 2-13 stability range

These properties enable lifetime performance guarantees of 15+ years in electrical insulation components.

Leading Global Mica Suppliers Comparison

| Supplier | Production Capacity | Material Grades | Processing Technology | Certifications | Lead Time |

|---|---|---|---|---|---|

| GlobalMica Group | 120,000 MT/year | 5 muscovite, 3 vermiculite grades | Laser-cut precision (±0.01mm) | AS9100D, ISO 14001 | 2-4 weeks |

| ElektroMica Co. | 85,000 MT/year | Specialty dielectric grades | Plasma surface treatment | IATF 16949, UL recognized | 3-5 weeks |

| ThermalShield Minerals | 68,000 MT/year | Fireproof vermiculite concentrates | Microwave exfoliation | ASTM C516, EN 13501-1 | 1-3 weeks |

Customized Material Solutions

Material engineering adapts properties to demanding environments. For aerospace applications, muscovite suppliers impregnate sheets with epoxy-silicate hybrids achieving 400°C continuous service temperatures. Automotive battery insulation utilizes surface-modified vermiculite with ionic conductivity below 10-8 S/cm. Common customization options include:

- Precision fabrication: CNC cutting to 0.002" tolerance

- Surface treatments: Hydrophobic coatings reducing moisture absorption by 87%

- Hybrid composites: Glass-mica laminates for structural components

- Thermal enhancement: Exfoliated vermiculite blends for 1,200°C fire protection

Industrial Application Success Stories

Mica components enable breakthrough performance across sectors. Electronics manufacturers using precision-cut muscovite insulators reduced thermal runaway incidents by 92% in lithium battery packs. Construction projects incorporating surface-modified vermiculite in sprays achieved 240-minute fire ratings - exceeding building code requirements by 300%. In India's railway modernization, custom-engineered mica sheets reduced transformer failure rates by 78% under monsoon conditions.

Sustainable Sourcing and Ethical Compliance

Responsible mica suppliers implement blockchain traceability systems tracking material from mine to factory, with 98% of compliant producers now following OECD Due Diligence Guidance. Processing technologies have reduced water consumption by 65% since 2015 while zero-waste facilities reclaim 96% of processing water. Independent audits confirm adherence to:

- Responsible Mica Initiative (RMI) standards

- EICC-GeSI supply chain protocols

- UN Sustainable Development Goals 8 and 12

Selecting Reliable Mica Suppliers

Procurement decisions should evaluate technical capability alongside compliance. Top-tier muscovite mica suppliers provide third-party verified material test reports (MTRs) with batch traceability. For critical applications, on-site audits of processing facilities verify quality control measures maintaining ±3% property tolerances. Leading suppliers now offer performance warranties extending 10 years on dielectric products, backed by 24/7 technical support teams. Production certification should include material-specific approvals such as Mil-I-24768/3 for aerospace applications.

(mica suppliers)

FAQS on mica suppliers

Q: Where can I find reliable global mica suppliers?

A: Reputable mica suppliers operate globally with significant hubs in India, China, and Brazil. Verify suppliers through certifications like ISO and Responsible Mica Initiative compliance. Always request material safety data sheets and sample batches for quality testing.

Q: What distinguishes reputable muscovite mica suppliers?

A: Top muscovite mica suppliers provide chemically inert, heat-resistant sheets with >98% purity levels. They offer multiple grades (from crude to micronized) with documented traceability to ethical mines. Key differentiators include consistent particle sizing and low iron-content guarantees.

Q: Do vermiculite suppliers typically offer other minerals?

A: Yes, most premium vermiculite suppliers also distribute complementary minerals like perlite, expanded clay aggregates, and phlogopite mica. They often provide both exfoliated and crude vermiculite grades for construction, horticulture, and industrial applications through integrated supply chains.

Q: How do mica suppliers ensure ethical sourcing compliance?

A: Leading mica suppliers enforce blockchain traceability systems from mine to processing facilities and participate in third-party audits. They adhere to OECD Due Diligence Guidance, maintain child-labor-free certifications, and implement community welfare programs in mining regions to meet international compliance standards.

Q: What are vermiculite suppliers' packaging options?

A: Vermiculite suppliers typically offer custom packaging from 1kg resealable bags to 1-ton super sacks with moisture barriers. Most provide vacuum-compressed bales to optimize shipping volume for expanded vermiculite. Industrial-grade options include bulk hopper trucks and UV-resistant woven polypropylene sacks.

-

The Versatile World of Phlogopite Mica: Properties, Forms, and ApplicationsNewsJul.14,2025

-

The Versatile Applications of Calcined Mica: From Decoration to Industrial UseNewsJul.14,2025

-

The Role of Muscovite Mica in Industrial Insulation MaterialsNewsJul.14,2025

-

The Benefits of Using Expanded Clay Pebbles in Hydroponics and Soil GardeningNewsJul.14,2025

-

Innovative Applications of Mica Flake in Paints and CoatingsNewsJul.14,2025

-

Gardening Expanded Clay Usage: A Complete GuideNewsJul.14,2025

-

The Use of Natural Mica Powder in Skincare ProductsNewsJun.11,2025