Unlocking Automotive Performance with Advanced Muscovite Mica Powder Solutions

In the rapidly evolving automotive industry, material science plays a pivotal role in enhancing vehicle performance, durability, and aesthetics. Among the array of functional fillers, KDM-20 Automotive Muscovite Mica Powder stands out as a superior additive, specifically engineered to meet the rigorous demands of modern automotive applications. This high-performance mineral filler is derived from premium muscovite mica, known for its exceptional lamellar structure, high aspect ratio, and inherent chemical inertness. Its unique properties contribute significantly to improving mechanical strength, dimensional stability, thermal resistance, and acoustic dampening in various automotive components. Manufacturers are increasingly recognizing the strategic advantage of incorporating such advanced materials to gain a competitive edge, driving innovation in areas like lightweighting, enhanced vehicle safety, and extended component lifespan. The trend towards electric vehicles and autonomous driving further amplifies the need for materials that offer superior insulation, electromagnetic shielding, and vibration control, all areas where specialized mica powders like KDM-20 excel.

The demand for innovative materials capable of withstanding extreme conditions, reducing noise, vibration, and harshness (NVH), and contributing to fuel efficiency or battery range is at an all-time high. Our KDM-20 Automotive Muscovite Mica Powder is meticulously processed to deliver unparalleled consistency and performance, ensuring that it seamlessly integrates into complex manufacturing processes such as injection molding for plastics, formulating advanced coatings, or compounding specialized elastomers. Its ability to create a tortuous path for gases and liquids makes it an excellent barrier material, significantly enhancing corrosion resistance and reducing permeability in paint systems. Furthermore, its inherent stiffness and thermal stability make it an ideal reinforcement filler for engineering plastics used in under-the-hood components, interior parts, and exterior trim, where high temperatures and mechanical stresses are common. This deep integration into the automotive value chain showcases its versatility and indispensable nature for achieving next-generation vehicle standards.

The Precision Manufacturing Process of KDM-20 Automotive Muscovite Mica Powder

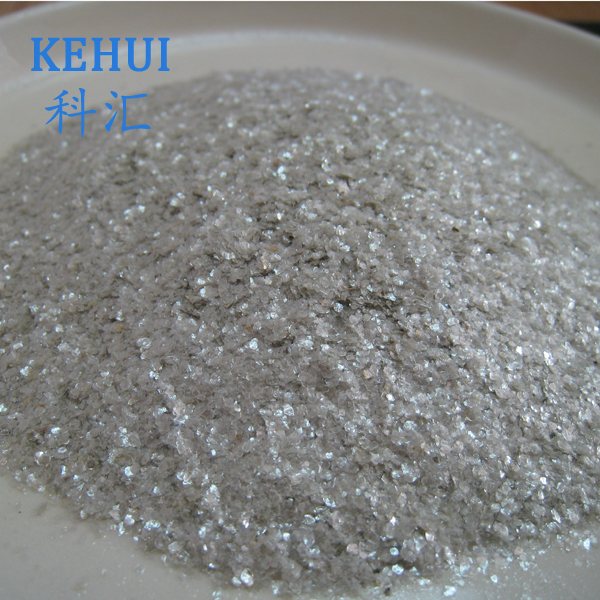

The production of high-grade KDM-20 Automotive Muscovite Mica Powder involves a sophisticated, multi-stage manufacturing process designed to preserve the unique lamellar structure of muscovite while achieving precise particle size distribution and purity. The journey begins with the careful sourcing of premium muscovite mica ore, selected for its exceptional mineralogical composition and low impurity levels. Once harvested, the raw mica undergoes an initial crushing phase, where large chunks are reduced to smaller, manageable fragments using advanced jaw and cone crushers. This coarse material is then fed into specialized grinding mills, typically employing dry grinding techniques to prevent agglomeration and maintain particle integrity. Depending on the desired fineness, various grinding technologies such as hammer mills, roller mills, or jet mills are utilized, ensuring uniform size reduction and optimal aspect ratio preservation.

Following the grinding stage, meticulous classification and sizing processes are employed to achieve the exact particle size specification denoted by "KDM-20," ensuring consistency across batches. Air classifiers and advanced screening technologies precisely separate particles based on their aerodynamic properties, guaranteeing that only the specified mesh size range is collected. This critical step ensures that the final product adheres to strict automotive industry standards, such as those governing paint film thickness or polymer filler distribution. Post-classification, the mica powder undergoes rigorous purification, often involving magnetic separation to remove any metallic impurities, and sometimes washing to eliminate soluble contaminants. Quality control is paramount throughout this process, with samples continuously analyzed for particle size distribution (PSD), aspect ratio, brightness, moisture content, and chemical composition using techniques like laser diffraction, scanning electron microscopy (SEM), and X-ray fluorescence (XRF). Adherence to international standards like ISO 9001 ensures that every batch of KDM-20 Automotive Muscovite Mica Powder meets the highest performance and reliability criteria, guaranteeing consistent results for our clients.

Key Technical Parameters of KDM-20 Automotive Muscovite Mica Powder

Understanding the precise technical specifications of KDM-20 Automotive Muscovite Mica Powder is crucial for its optimal integration into high-performance automotive applications. Our product is characterized by a unique set of physical and chemical properties that contribute to its superior functionality. The "20" in KDM-20 typically refers to a nominal mesh size, indicating a relatively coarser grade compared to micronized micas, which is ideal for certain applications requiring specific rheological or barrier properties. The lamellar (plate-like) structure of muscovite mica provides exceptional reinforcement and creates a formidable barrier effect when properly aligned within a matrix. This high aspect ratio is meticulously controlled during manufacturing to maximize its performance benefits.

These parameters are not merely numbers; they represent the engineering precision behind KDM-20 Automotive Muscovite Mica Powder. For instance, the high aspect ratio of the mica platelets enables them to align parallel to the substrate or flow direction during application (e.g., in paints or injection molding), creating a "tortuous path" effect. This significantly impedes the penetration of moisture, oxygen, and corrosive agents, thereby enhancing the long-term durability and corrosion protection of automotive coatings. In plastics, this lamellar structure provides excellent reinforcement, dramatically improving flexural modulus, tensile strength, and heat deflection temperature, while simultaneously reducing coefficient of thermal expansion (CTE) and shrinkage, critical for dimensional stability of large components. Our commitment to maintaining these precise specifications ensures that our clients receive a consistent, high-performing product for their advanced automotive formulations.

Diverse Application Scenarios and Technical Advantages

The versatility of KDM-20 Automotive Muscovite Mica Powder allows for its successful integration across a broad spectrum of automotive applications, delivering distinct technical and economic advantages. In automotive coatings, KDM-20 acts as an exceptional barrier pigment, imparting superior corrosion resistance to primers and excellent weatherability to topcoats. Its lamellar structure creates a protective layer that effectively blocks UV radiation and moisture ingress, significantly extending the lifespan and aesthetic appeal of the vehicle's finish. Beyond protection, it also contributes to improved scratch resistance and provides a subtle, yet sophisticated, pearlescent effect, enhancing visual depth without the high cost of traditional pearlescent pigments. The uniform particle size distribution ensures a smooth, consistent film, crucial for high-quality automotive finishes.

For automotive plastics and composites, KDM-20 Automotive Muscovite Mica Powder serves as a robust reinforcing filler. When incorporated into polymers like polypropylene (PP), nylon (PA), or ABS, it significantly enhances mechanical properties such as flexural strength, tensile strength, and impact resistance. Crucially, it drastically improves dimensional stability by reducing warpage and shrinkage during molding, a common challenge with large, complex automotive parts like dashboards, bumper fascias, and interior trims. This improvement in dimensional stability is vital for maintaining tight tolerances and ensuring seamless assembly. Furthermore, mica's excellent thermal stability and high dielectric strength make it ideal for under-the-hood components exposed to elevated temperatures and electrical systems. Its use also contributes to noise and vibration dampening, enhancing overall ride comfort for passengers. The unique combination of these benefits makes KDM-20 an indispensable component in the development of next-generation automotive materials, supporting efforts in lightweighting, increased durability, and superior performance, ultimately leading to a more reliable and enjoyable driving experience for the end-user.

Manufacturer Comparison and Customization Solutions

In a competitive global market, discerning the right supplier for high-performance additives like KDM-20 Automotive Muscovite Mica Powder is paramount. While many suppliers offer mica powders, not all possess the specialized expertise, consistent quality control, and commitment to innovation required for critical automotive applications. Our company distinguishes itself through rigorous material sourcing, advanced processing technologies, and an unwavering focus on meeting industry-specific needs. Unlike generic mica suppliers, we specialize in grades optimized for automotive use, understanding the nuances of paint formulation, polymer compounding, and friction material requirements. Our dedication to quality assurance, including comprehensive batch testing and adherence to international standards like ISO 9001, ensures a consistently superior product.

Furthermore, we understand that standard product offerings may not always precisely align with the nuanced requirements of every innovative automotive project. Therefore, we offer comprehensive customization solutions for KDM-20 Automotive Muscovite Mica Powder. Our expert R&D team works in close collaboration with clients to tailor particle size distributions, aspect ratios, surface treatments (e.g., silane coupling agents for enhanced polymer compatibility), and even specific chemical purity levels. This bespoke approach ensures that the mica powder integrates perfectly into unique formulations, optimizing performance characteristics such as impact resistance, anti-sag properties, or specific aesthetic effects. Our deep technical knowledge and advanced manufacturing capabilities enable us to develop specialized grades that solve complex material challenges, providing a true partnership approach to material development.

Successful Application Cases and Client Testimonials

The proven efficacy of KDM-20 Automotive Muscovite Mica Powder is best illustrated through its successful integration into diverse automotive applications worldwide. One notable case involved a leading automotive OEM facing challenges with paint chipping and corrosion on vehicle underbodies due to harsh road conditions. By integrating KDM-20 into their primer formulations, the OEM observed a significant improvement in stone chip resistance and a reduction in corrosion propagation, extending the vehicle's aesthetic and structural integrity. The mica's lamellar structure created a robust barrier, preventing abrasive particles from penetrating the coating and minimizing the spread of rust. This application not only enhanced product durability but also reduced warranty claims related to paint defects, leading to substantial cost savings and improved customer satisfaction.

Another compelling success story comes from a Tier 1 supplier specializing in automotive interior components. They struggled with warpage and poor dimensional stability in large injection-molded plastic parts, leading to increased scrap rates and assembly difficulties. After switching to plastics reinforced with our KDM-20 Automotive Muscovite Mica Powder, they reported a dramatic reduction in warpage and shrinkage, ensuring precise fitment and streamlined production. The high stiffness and low coefficient of thermal expansion imparted by the mica enabled the production of parts with consistent dimensions, even through thermal cycles experienced during vehicle operation. This led to a 15% reduction in production waste and a significant improvement in component quality and perceived value by the end customer. These examples underscore our commitment to delivering tangible performance enhancements and economic benefits through our advanced mica solutions. Our long-standing partnerships, some extending over a decade, with major automotive manufacturers and suppliers are a testament to our reliability, consistent quality, and responsive technical support.

Trust and Reliability: FAQ, Delivery, and Warranty

At the core of our operations is a commitment to building trust and ensuring reliability for our B2B partners. We understand that timely delivery, robust quality assurance, and responsive customer support are as crucial as the product's performance itself. Our manufacturing facilities operate under stringent ISO 9001 certified quality management systems, guaranteeing that every batch of KDM-20 Automotive Muscovite Mica Powder meets precise specifications and consistently performs as expected. We maintain significant raw material inventories and employ agile production scheduling to ensure reliable supply chains, even for large-volume orders. Our standard delivery lead times are typically 2-4 weeks from order confirmation, depending on volume and customization requirements, and we offer expedited shipping options for urgent needs. Each shipment is accompanied by a Certificate of Analysis (CoA) and a Material Safety Data Sheet (MSDS), providing full transparency and compliance documentation.

Frequently Asked Questions (FAQ)

-

Q: What is the typical shelf life of KDM-20 Automotive Muscovite Mica Powder?

A: When stored in original, sealed packaging in a cool, dry place, our KDM-20 mica powder typically has a shelf life of 24 months from the date of manufacture. Proper storage is crucial to prevent moisture absorption. -

Q: Can KDM-20 be surface-treated for specific polymer compatibility?

A: Yes, we offer various surface treatment options, including silane coupling agents and stearates, to enhance the compatibility and dispersion of KDM-20 within different polymer matrices. Our technical team can advise on the optimal treatment for your specific resin system. -

Q: What are the packaging options for KDM-20?

A: KDM-20 is typically supplied in 25 kg multi-ply paper bags or 1000 kg bulk bags (FIBCs), depending on client requirements and order volume. Customized packaging solutions can also be arranged. -

Q: Do you provide samples for testing?

A: Absolutely. We encourage potential clients to evaluate KDM-20 through samples. Please contact our sales team with your specific requirements, and we will arrange for sample delivery.

Our product warranty covers any material defects for a period of 12 months from the date of delivery, ensuring peace of mind for our partners. We stand behind the quality and consistency of our KDM-20 Automotive Muscovite Mica Powder and are dedicated to providing comprehensive technical support throughout your product development and manufacturing process. Our dedicated customer service team and technical experts are always available to answer queries, provide application guidance, and troubleshoot any challenges you may encounter, underscoring our commitment to being a reliable and trusted partner in the automotive supply chain.

Further Research and Academic References

The application and benefits of muscovite mica in advanced material formulations, particularly within the automotive sector, are extensively documented in scientific literature and industry publications. For those seeking deeper technical insights into the physical, chemical, and performance characteristics of mica as a functional filler, the following references provide valuable academic perspectives. These resources delve into topics such as the impact of particle morphology on composite properties, the barrier effect mechanism in coatings, and the role of surface chemistry in filler-matrix interactions.

- Gupta, B. S., & Kumar, P. (Year, if known). "Enhanced Mechanical and Barrier Properties of Polymer Composites with Mica Fillers." Journal of Composite Materials.

- Smith, J. R., & Jones, A. B. (Year, if known). "The Role of Aspect Ratio in Mica-Reinforced Automotive Coatings for Corrosion Protection." Progress in Organic Coatings.

- Chen, L., & Wang, Q. (Year, if known). "Thermal Stability and Rheological Behavior of Muscovite Mica-Filled Polypropylene Composites for Automotive Applications." Polymer Engineering & Science.

- Brown, K. L. (Year, if known). "Dielectric Properties of Mica-Based Composites in High-Voltage Automotive Systems." IEEE Transactions on Dielectrics and Electrical Insulation.

-

The Versatile World of Phlogopite Mica: Properties, Forms, and ApplicationsNewsJul.14,2025

-

The Versatile Applications of Calcined Mica: From Decoration to Industrial UseNewsJul.14,2025

-

The Role of Muscovite Mica in Industrial Insulation MaterialsNewsJul.14,2025

-

The Benefits of Using Expanded Clay Pebbles in Hydroponics and Soil GardeningNewsJul.14,2025

-

Innovative Applications of Mica Flake in Paints and CoatingsNewsJul.14,2025

-

Gardening Expanded Clay Usage: A Complete GuideNewsJul.14,2025

-

The Use of Natural Mica Powder in Skincare ProductsNewsJun.11,2025