Strategic Importance of Calcined Mica in Advanced Welding Electrodes

In the demanding field of industrial welding, the composition of electrode coatings critically dictates weld quality, arc stability, and overall performance. Among the various mineral fillers, 60mesh Calcined Mica Powder for Welding Electrode stands out as a superior additive, offering distinct advantages that elevate the efficacy of welding processes. Its unique lamellar structure and high thermal stability, achieved through controlled calcination, provide essential functions within the electrode flux. This fine-grade powder acts as an excellent arc stabilizer, a potent insulator, and a crucial component in shaping the slag system, ultimately contributing to a smoother welding operation and enhanced metallurgical properties of the weld bead. Manufacturers and technical decision-makers increasingly prioritize such specialized materials to meet the stringent quality demands of modern fabrication and construction projects across diverse sectors.

The global welding industry is currently experiencing significant trends driven by the increasing demand for high-strength, durable welds in sectors like infrastructure development, shipbuilding, and automotive manufacturing. This trend necessitates the use of advanced electrode formulations capable of delivering consistent, high-quality results under various operating conditions. The incorporation of calcined mica powder addresses key challenges such as spatter reduction, improved slag removal, and enhanced mechanical properties of the deposited metal, thereby ensuring cost-effectiveness and operational efficiency. Furthermore, the push for automated and robotic welding systems places even greater emphasis on the consistency and reliability offered by meticulously formulated welding consumables, making the precise granulometry of 60mesh mica powder particularly valuable.

Comprehensive Manufacturing Process of Calcined Mica Powder

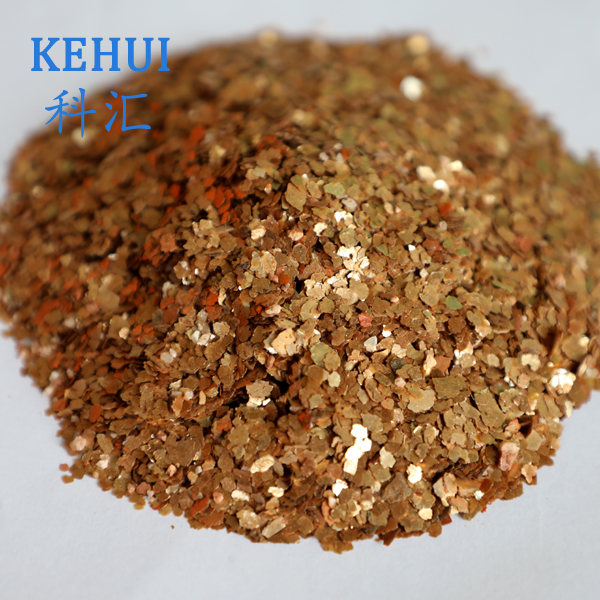

The production of high-quality 60mesh Calcined Mica Powder for Welding Electrode involves a multi-stage, meticulously controlled process designed to optimize its physical and chemical properties for electrode applications. It begins with the careful selection of raw muscovite mica, known for its excellent dielectric strength and thermal resistance. This raw mica undergoes an initial crushing phase to reduce its size, followed by precise grinding. The critical step is calcination, where the mica is heated to high temperatures (typically between 800°C and 1000°C) in a controlled environment. This thermal treatment removes volatile components, enhances the mica's thermal stability, and alters its surface chemistry, making it more suitable for integration into electrode coatings without compromising the integrity of the flux.

Following calcination, the material undergoes further fine grinding and pulverization to achieve the specified 60-mesh particle size, ensuring uniform distribution within the electrode coating. This precision in particle size is paramount for consistent arc performance and slag formation. Strict quality control measures are applied throughout the entire process, adhering to international standards such as ISO 9001 for quality management. Batch testing for chemical composition, moisture content, specific gravity, and particle size distribution (e.g., using ASTM E11 sieve analysis) ensures each batch meets the rigorous demands of welding electrode manufacturers. This rigorous process guarantees a product that delivers superior arc stability, improved slag detachability, and enhanced mechanical properties in the final weld, proving vital in industries like heavy manufacturing, pipeline construction, and structural steel fabrication.

Technical Specifications and Performance Advantages

The precise technical specifications of 60mesh Calcined Mica Powder for Welding Electrode are meticulously engineered to confer specific benefits in flux coatings. Its lamellar structure provides effective barrier properties, contributing to arc stability and preventing unwanted reactions within the molten weld pool. The calcination process enhances its thermal insulation properties, ensuring a more stable arc and protecting the core wire from excessive heat. Furthermore, the controlled mesh size facilitates consistent mixing and extrusion during electrode manufacturing, leading to homogeneous coatings and predictable welding performance. Key parameters often include particle size distribution, moisture content, loss on ignition (LOI), and specific chemical composition, all of which directly impact the electrode's functionality.

Typical Specifications for 60mesh Calcined Mica Powder

| Parameter | Typical Value | Benefit in Welding Electrode |

|---|---|---|

| Mesh Size (Tyler Equivalent) | Min. 95% passing 60 mesh (250 µm) | Ensures uniform flux coating, consistent arc characteristics, and smooth extrusion. |

| Moisture Content | ≤ 0.5% | Minimizes hydrogen pick-up in weld metal, reducing porosity and cracking. |

| Loss on Ignition (LOI) @ 1000°C | ≤ 1.0% | Indicates excellent thermal stability; prevents excessive gas evolution during welding. |

| Specific Gravity | 2.7 - 2.9 g/cm³ | Aids in controlled melt pool fluidity and slag formation. |

| Bulk Density | 0.15 - 0.25 g/cm³ | Influences packing density in flux coatings, affecting coating thickness and stability. |

| Dielectric Strength | Excellent | Contributes to arc stability and re-ignition properties. |

The incorporation of 60mesh Calcined Mica Powder for Welding Electrode directly translates into tangible performance improvements: enhanced arc stability due to its insulative properties, superior slag detachability facilitated by its lamellar structure, and reduced spatter, leading to less post-weld cleaning. Furthermore, it contributes to a smoother weld bead appearance and can positively influence the mechanical properties of the weld metal. These benefits are critical for high-volume manufacturing environments where consistency, efficiency, and final product quality are paramount, driving down operational costs and increasing productivity in applications such as structural welding, pipe fabrication, and general maintenance welding.

Application Scenarios and Industry Benefits

60mesh Calcined Mica Powder for Welding Electrode finds its indispensable place across a wide array of demanding industrial applications where robust and reliable welds are non-negotiable. It is a cornerstone component in the formulation of various types of welding electrodes, including those designed for mild steel, low alloy steel, and stainless steel. In the construction industry, particularly for large-scale infrastructure projects like bridges, high-rise buildings, and industrial facilities, electrodes containing calcined mica ensure structural integrity and longevity. The improved arc characteristics and enhanced slag control offered by the mica are vital for achieving high-quality welds in diverse positions and challenging environmental conditions, ultimately contributing to project efficiency and safety.

Beyond construction, its applications extend into the highly specialized fields of shipbuilding, where weld quality directly impacts vessel safety and performance, and the automotive sector, focusing on both manufacturing and repair. In these industries, the use of electrodes optimized with 60mesh Calcined Mica Powder for Welding Electrode leads to significant benefits such as reduced post-weld processing time due to cleaner welds and easily removable slag. This translates into substantial cost savings and increased throughput. For heavy machinery and equipment fabrication, where welds are subjected to extreme stresses and fatigue, the enhanced mechanical properties and reduced defect rates provided by mica-containing electrodes are critical for the durability and operational lifespan of the final product. The consistent performance of these electrodes also plays a crucial role in minimizing material waste and rework, aligning with principles of lean manufacturing.

Strategic Supplier Selection and Customization

Selecting a reliable supplier for 60mesh Calcined Mica Powder for Welding Electrode is a strategic decision for manufacturers of welding consumables. Beyond standard product specifications, a reputable vendor offers consistency in quality, robust supply chain management, and technical support. Manufacturers should look for suppliers who adhere to strict quality control protocols, including detailed batch analysis reports and certifications like ISO 9001. A key differentiator lies in the supplier's ability to provide tailored solutions. While 60 mesh is a common standard, specific welding electrode formulations might benefit from slight variations in particle size distribution, purity levels, or surface treatments. Collaborating with a supplier capable of customizing these parameters ensures optimal integration into unique electrode designs, meeting specialized performance criteria for niche applications or proprietary blends.

When evaluating potential partners, consider their experience in the industrial mineral sector and their track record of serving the welding industry. Companies with extensive R&D capabilities can offer valuable insights into material optimization, helping electrode manufacturers innovate and improve their product lines. Furthermore, a transparent supply chain, demonstrating ethical sourcing and sustainable production practices, is becoming increasingly important for B2B decision-makers. The ability to provide comprehensive technical data sheets, safety data sheets (MSDS), and prompt customer support differentiates a merely transactional relationship from a true strategic partnership, fostering long-term reliability and mutual growth in the competitive market of welding consumables, ultimately contributing to the success of projects in demanding environments.

Ensuring Quality and Trustworthiness: in Action

The principles of Expertise, Experience, Authoritativeness, and Trustworthiness () are fundamental to the consistent delivery of high-performance 60mesh Calcined Mica Powder for Welding Electrode. Expertise is demonstrated through deep understanding of mica mineralogy, calcination processes, and the specific demands of welding electrode formulations. This includes scientific insights into how mica's lamellar structure contributes to arc stability and slag management, and how specific impurity levels affect weld quality. Experience is reflected in years of successful product deployment, understanding nuanced customer needs, and adapting to evolving industry standards. For instance, feedback from leading electrode manufacturers regarding improved coating homogeneity or reduced spatter provides tangible proof of product efficacy in real-world scenarios, validating the practical benefits for end-users like professional welders.

Authoritativeness is built upon verifiable credentials, such as ISO 9001 certification for quality management systems, adherence to ASTM or other relevant material testing standards, and a track record of consistent product performance across diverse applications. Collaboration with research institutions or industry bodies, and the publication of technical white papers, further solidify this standing. Trustworthiness is cultivated through transparent business practices, including clear product specifications, consistent delivery timelines, and robust customer support. This encompasses accessible technical service teams ready to assist with formulation challenges, a clear warranty policy ensuring product conformance, and efficient global logistics to meet demanding production schedules. Providing FAQs that address common technical inquiries and usage best practices further empowers clients and builds confidence in the supplier's commitment to excellence and reliability.

Frequently Asked Questions (FAQ)

- Q: What is calcined mica, and how does it differ from raw mica for welding electrodes?

A: Calcined mica is mica that has been heat-treated at high temperatures (800-1000°C) to remove volatile components and enhance its thermal stability and insulation properties. This makes it superior to raw mica for welding electrodes, as it ensures consistent performance and reduces gas evolution during welding. - Q: How does the 60 mesh particle size benefit electrode performance?

A: A 60 mesh (250 µm) particle size ensures uniform dispersion within the electrode flux coating, promoting stable arc characteristics, consistent slag formation, and smooth extrusion during manufacturing. This precision reduces defects and enhances weld quality. - Q: What quality certifications does your 60mesh Calcined Mica Powder meet?

A: Our production processes adhere to ISO 9001 quality management standards. Each batch undergoes rigorous testing for particle size distribution (e.g., ASTM E11), moisture content, and chemical composition to ensure consistent quality and performance. - Q: What is the typical lead time for large orders of calcined mica powder?

A: Lead times vary based on order volume and current production schedules. We strive for efficient delivery and maintain robust supply chain logistics. Please contact our sales team with your specific requirements for a precise timeline. - Q: Is technical support available for optimizing electrode formulations with your mica?

A: Yes, our technical experts are available to provide comprehensive support and guidance on incorporating our 60mesh Calcined Mica Powder for Welding Electrode into your specific formulations to achieve optimal performance and address any unique challenges.

Delivery and Quality Assurance

We understand the critical importance of timely and reliable supply in the manufacturing sector. Our global logistics network is designed to ensure efficient delivery of 60mesh Calcined Mica Powder for Welding Electrode, minimizing lead times and supporting your production schedules. Each shipment is accompanied by comprehensive documentation, including Certificates of Analysis (COA) and Material Safety Data Sheets (MSDS), confirming product specifications and safety compliance. We stand by the quality of our product with a clear warranty that guarantees conformance to specified technical parameters, providing our partners with complete peace of mind and unwavering confidence in their raw material supply. Our commitment to continuous improvement and customer satisfaction underscores every aspect of our operations, from raw material sourcing to final product delivery and post-sales support.

Conclusion: Driving Excellence in Welding Performance

The strategic integration of high-grade 60mesh Calcined Mica Powder for Welding Electrode is more than just an ingredient choice; it represents a commitment to superior welding performance, efficiency, and reliability in critical industrial applications. Its distinct properties—enhanced thermal stability, precise particle size, and unique lamellar structure—collectively contribute to improving arc characteristics, optimizing slag formation, and ultimately enhancing the mechanical properties and aesthetics of the weld bead. As industries continue to demand higher standards for material integrity and production efficiency, the role of specialized additives like calcined mica becomes increasingly vital. Partnering with a supplier who not only understands these technical nuances but also champions consistency, quality assurance, and responsive customer support, ensures a competitive edge for welding electrode manufacturers in a rapidly evolving global market.

References

- American Welding Society (AWS) Handbooks and Standards on Filler Metals and Fluxes.

- International Standards Organization (ISO) standards related to quality management and material testing in industrial minerals.

- Studies on the influence of mineral additives on welding arc stability and slag properties in flux-cored and covered electrodes.

- Research publications on the thermal and chemical stability of muscovite mica in high-temperature industrial applications.

-

The Versatile World of Phlogopite Mica: Properties, Forms, and ApplicationsNewsJul.14,2025

-

The Versatile Applications of Calcined Mica: From Decoration to Industrial UseNewsJul.14,2025

-

The Role of Muscovite Mica in Industrial Insulation MaterialsNewsJul.14,2025

-

The Benefits of Using Expanded Clay Pebbles in Hydroponics and Soil GardeningNewsJul.14,2025

-

Innovative Applications of Mica Flake in Paints and CoatingsNewsJul.14,2025

-

Gardening Expanded Clay Usage: A Complete GuideNewsJul.14,2025

-

The Use of Natural Mica Powder in Skincare ProductsNewsJun.11,2025